Using integrated renewables to transform cities into power-generating centers is key to Scarcity Zero because it helps reduce and eventually remove the demand municipalities place on regional electric grids. As urban regions eventually become net energy producers, we can generate more than they consume, which helps contribute to a nationwide abundance of inexpensive energy that can be devoted to the indefinite production of critical resources. The next step in the framework is to increase our base load power infrastructure, and scale a national energy abundance, to a dramatically higher tier.

“Base load” refers to the minimum amount of power that needs to be generated for a given region over time.[1] Today, this is met through larger “base load” power stations that are supplemented by smaller plants that engage when demand spikes. As base load stations are designed to be constantly operational and generate a lot of electricity, they are more expensive to construct and maintain, which encourages the use of cheaper fuels to power them.

Accordingly, most of our base load infrastructure is presently powered by fossil fuels (coal and natural gas), followed by enriched uranium and hydroelectric.[2] While far superior to environmentally toxic coal, hydroelectric and natural gas present their own ecological drawbacks.[3] Hydroelectric can only be deployed in limited locations, and enriched uranium is both limited in quantity and primarily deployed in reactor designs that present concerns of both weaponization and risks of catastrophic failure. To make matters worse, the majority of our base load infrastructure is decades old.[4] More than half of our base load power infrastructure was built before 1980, and 75% of our coal-fueled power plants are at least thirty years old with an average expected lifespan of forty years.[5]

Scarcity Zero seeks to solve these problems by replacing our base load infrastructure with next-generation technology that’s designed to work alongside other power systems intelligently, employing the same concepts of standardization and modularity that’s applied to integrated renewables. The technology it looks to for this role is a clean, safe and highly efficient form of atomic energy that comes from the element thorium – not enriched uranium – to provide an immense source of base load power for our national energy grids.

In saying this, it’s important to mention that nuclear power can be a polarizing subject – and for good reason. Atomic energy can be dangerous. It can make weapons of mass destruction, cause regionally-devastating meltdowns and produce toxic waste that lasts for millennia. Risks aside, certain types of nuclear power can also be incredibly expensive, leading many to doubt its long-term economic viability. For these reasons, nuclear has become politically controversial in much of the world, especially within the United States.

Yet while many of these concerns are conceptually valid, nearly every single one centers on the consequences of nuclear reactors that run on a combination of enriched uranium and pressurized water. And the reason most reactors have worked this way in the past is because atomic energy as we know it was born from initiatives designed to produce both nuclear weapons and civilian power as directed from national leadership during the Cold War. Consequently, there are few ways to decouple “traditional” nuclear reactors from nuclear weapons development. Any attempt to do so with certainty quickly reaches into the billions of dollars, to say nothing of the ecological risks and their accompanying expenses.

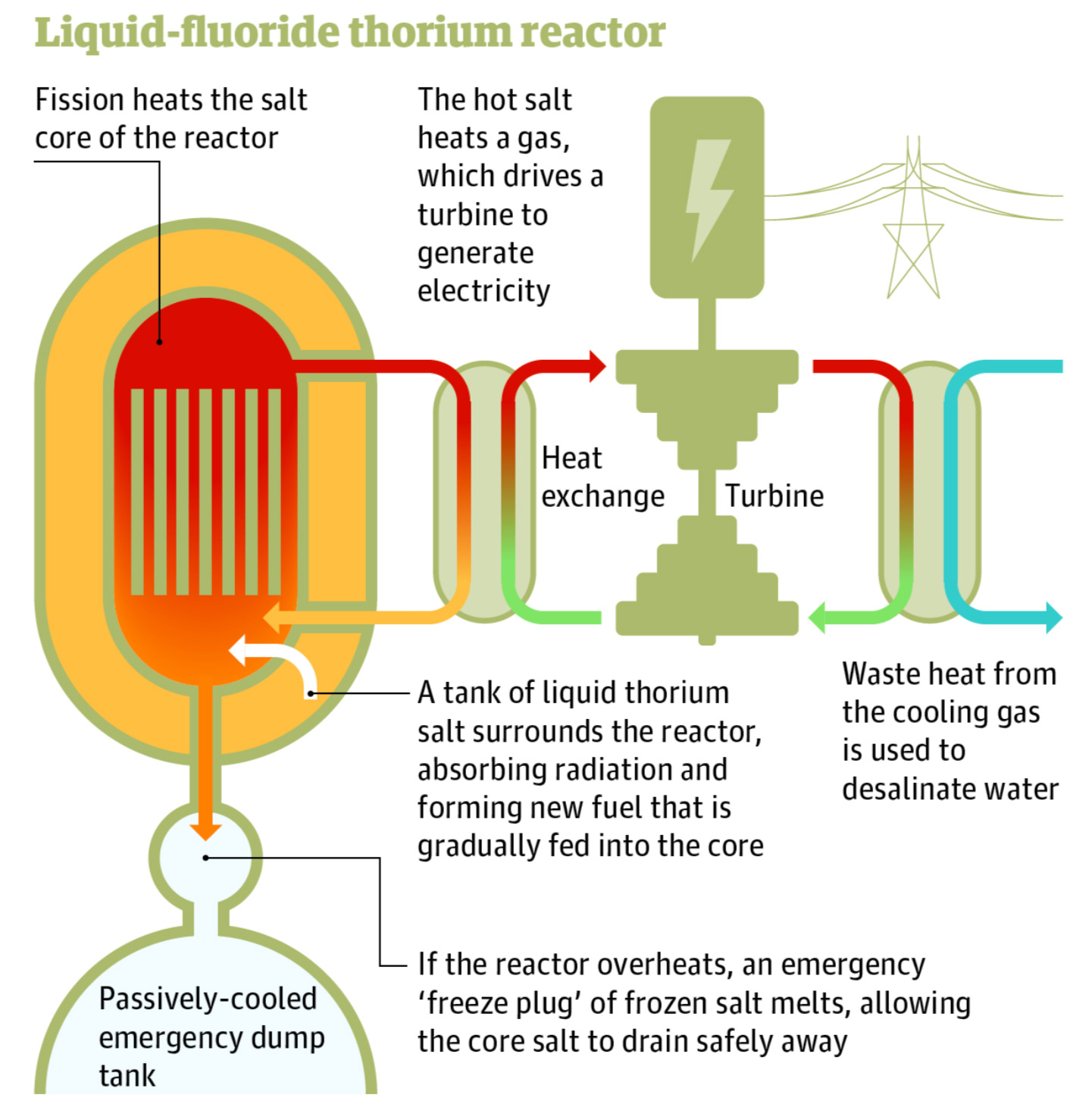

But thorium is not “traditional” nuclear. Reactors fueled by thorium don’t use water and aren’t pressurized – the main issue behind reactor “meltdowns.” Thorium reactors don’t use solid fuel, either – the entire reactor core is liquid. It’s physically impossible for one to “melt down” like their pressurized-water counterparts and they can’t wreak serious environmental havoc if sabotaged. Thorium reactors can consume both nuclear waste and weapons-grade nuclear material as fuel, but at the same time are difficult to use to build nuclear weapons. Their waste has a minimal environmental footprint as well, and that waste becomes safe over decades as opposed to millennia.

Thorium reactors further fit the requirements of Scarcity Zero. They operate at high temperature and offer plenty of excess energy for supplemental resource production. They can be built to a single standard, small in size and modular in function that can be mass produced and deployed anywhere in the world. The designs being proposed already include the cogenerative features that Scarcity Zero seeks for a dynamic energy framework. As we’ll see later in this chapter, the technology has been proven to work impressively and has further seen financial investments well into the billions from seven countries (as of this writing) – including the United States.[7]

But in advocating their benefits, it’s important to also note that thorium reactors have their criticisms. Some come from people simply opposed to nuclear power as a concept, favoring exclusive use of renewables. Others come from nuclear engineers, cautioning against discarding traditional reactor designs that, while riskier, have seen the lion’s share of research and development with regards to atomic energy. Others still come from people who doubt the viability of a science that – to be fair – has a contingent of enthusiastic backers who at times oversell thorium’s benefits without recognizing the challenges, however solvable, to deploying the technology on a large scale.

These criticisms are taken seriously by this writing and will be addressed directly in this chapter, situated fairly and factually within the context of the resource, climate and energy challenges humanity will be facing in the future. This discussion will also draw a noteworthy distinction between renewables and thorium, and directly address why we even need both in the first place.

Good point. Renewables Are Awesome. So Why Do We Need Thorium?

As a framework, Scarcity Zero functions on the recognition that until we develop true fusion energy[8] there will be no one singular technology that is capable of meeting humanity’s energy and resource requirements. Renewables are essential to city-level energy reduction and eventual independence, all the more so as their integration increases in scale. But by themselves, renewables fall far short of the threshold needed to reliably meet the demands of base load power nationwide, which itself is a far lower bar than the levels of energy we require to solve resource scarcity and climate change.

Further, even if renewables could generate enough energy to solve these problems, the carbon emissions behind their base material extraction, manufacture, transport and installation at sufficient scale would undermine the endeavor from the start. Solar and wind power, as we’ll review later in this chapter, requires lots of raw materials to construct – between 10,000-17,000 metric tons to generate a single terawatt.[9] That says nothing of transmission or storage – nor the energy needed to source, process and integrate materials for those functions. It also says nothing of the considerable difficulties presented by their end-state disposal.

That’s not a problem if the energy used in every step the renewable manufacturing chain is carbon-neutral, but only clean nuclear is capable of generating that level of carbon-free energy as a modular standard. Further, only clean nuclear is capable of generating enough carbon-free energy to power auxiliary functions of synthetic resource production. To see why this is the case, let’s compare nuclear and solar at scale:

One of the largest solar power stations in the world is the Topaz Solar Farm in southern California. At a cost of $2.5 billion and spanning 7.3 square miles, the Topaz Solar Farm deploys nine million solar modules to generate an aggregate of 1,270 gigawatt-hours annually.[10] That’s certainly impressive. But it’s dwarfed when compared to the generating capacity of base load nuclear.

The Limerick nuclear power plant in southeast Pennsylvania, for comparison, has a generating capacity of 2,270 megawatts and annually outputs 19,000 gigawatt-hours.[11] That plant is barely half the size of the Palo Verde nuclear plant in Arizona, which has a generating capacity of 3,942 megawatts and annually outputs 32,840 gigawatt-hours of energy.[12]

Even as one of the largest solar power stations in existence – located in one of the most solar-effective areas on the planet – the Topaz Solar Farm generates less than 5% of the output of a large base load nuclear power station.

Across a city – or many of them – that capacity definitely matters. Renewables serve the purpose of rapid installation, flexibility of deployment and integration within municipal infrastructure, uniquely suiting them for supplementing national energy generation and reducing regional energy demand – all the more so once integrated into the National Aqueduct. But it would take thousands of square miles at a cost of many trillions of dollars to meet our energy demands in full through renewables alone,[13] a threshold that modern nuclear reactors can meet at a fraction of the physical, material and economic footprint.

That’s where thorium comes in.

Like renewables, thorium’s role in the framework is to provide a nigh-unlimited source of clean electricity. Yet thorium can do so at a degree and to a density that presents an unrivaled capability to not only exceed our current base load infrastructure, but also present such an abundance of energy that it causes the price of electricity to plummet. Most critically, thorium is capable of this while also generating enough residual heat energy to power inexpensive resource production.

That’s the essential capability that only clean nuclear can meet on the scale we need to solve resource scarcity and climate change. We’ll devote the rest of this chapter to see how thorium reactors can serve as a vital component of Scarcity Zero, bridging the divide between nuclear and renewables while expanding our energy production capabilities and transforming our resource supply chain.

In doing so, we’ll be focusing on five key points:

- A brief overview of thorium and nuclear power.

- Why we don’t use thorium today.

- How thorium works differently than “traditional” nuclear.

- How we know thorium reactors are a feasible and economical source of power.

- Why criticisms of thorium are wrong on the facts

A Quick Note:

While The Next Giant Leap takes care to explain all technologies behind Scarcity Zero in detail, thorium reactors (and the nuclear science that makes them possible) are the most sophisticated and technically complex system in the framework. Further, in the interests of intellectual honesty, this chapter also takes care to fairly summarize and address criticisms to thorium + nuclear power and explain why they are wrong on the facts.

As such, while this chapter is written in accessible language that’s easy to understand even if you don’t have a technical background, it’s still the longest and most detailed in this book. If you’re feeling overwhelmed, please feel free to jump to Chapter Five: Water and Hydrogen and come back at any time to finish reviewing how thorium is key to a clean energy future.

So, What Is A Thorium Reactor?

When people think of nuclear power, they commonly think of a large facility with tall steam stacks, perhaps also containing potentially dangerous materials that could cause calamity under the wrong circumstances. That’s the classic “Pressurized Water Reactor” which works via a combination of pressurized water and enriched uranium. In contrast, Liquid Fluoride Thorium Reactors (LFTRs) use thorium within a high-temperature liquid moderator – no pressure needed – and they work in a way that avoids atomic energy’s most serious problems.[14] Here’s a short list of their highlights:

- LFTRs are highly efficient – hundreds of times more so than Pressurized Water Reactors.[15]

- LFTRs are extremely safe. Because their fuel and reactant are liquid and not under extreme pressure (unlike traditional reactors), it is physically impossible for them to “melt down.”[16]

- Thorium is more stable than other radioactive elements and is safe to handle in raw form unless ingested or inhaled. Additionally, it does not require additional enrichment to power a reactor.[17]

- LFTRs produce far less waste than Pressurized Water Reactors and can also consume both nuclear waste and weapons-grade nuclear material as fuel.[18] Of what small amounts of waste remain, it takes only decades for it to become safe as opposed to millennia with reactors powered by enriched uranium.[19]

- The LFTR’s thorium fuel supply is highly abundant – thorium is about as common as lead – making it thousands of times more plentiful than fuel-grade uranium (only about 0.7% of all uranium in Earth’s known land reserves).[20]

- The thorium fuel in LFTRs is difficult to weaponize. While theoretically possible, the weapon would be unstable, far weaker than traditional nuclear weapons, and would be significantly less practical for use in conflict.[21]

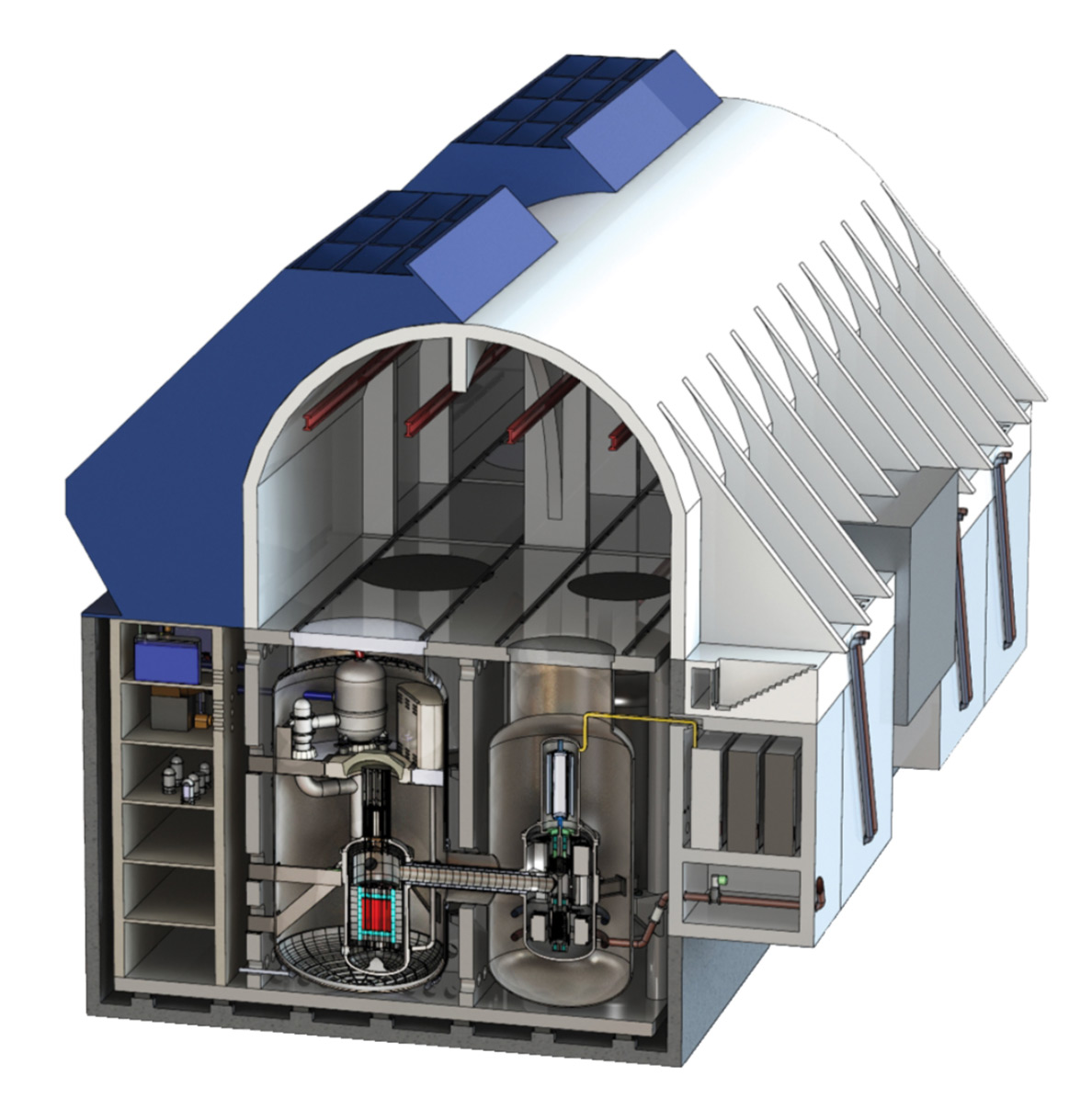

- As a result of their efficiency and safety, LFTRs can be much smaller than Pressurized Water Reactors. Where Pressurized Water Reactors often sit on multi-acre compounds and require large buffer zones in case of emergencies, LFTRs can be around the size of a house or even smaller.[22]

- LFTRs are significantly less expensive to build than Pressurized Water Reactors, and their small size allows them to be mass-produced on assembly lines in a standardized and modular capacity. That means nuclear reactors can become iterations of a product model as opposed to custom-built facilities. The cost savings presented by this capability are immense.[23]

- Although recent thorium designs are experimental, the technology is proven to work both reliably and impressively – an emphasis that will be elaborated upon within a later section of this chapter.

LFTRs are superior to today’s Pressurized Water Reactors in nearly every way possible, and their capabilities have been known to science since the 1960’s.[24] But that prompts an important question: why aren’t we using them today?

To answer that, we’ll need to cover some background that’s easier to understand by first reviewing a few terms surrounding atomic energy. What follows is a quick refresher from science class, or a primer if you’re not familiar with how nuclear power works. (Feel free to skim it, or to skip it now and refer to it as necessary.)

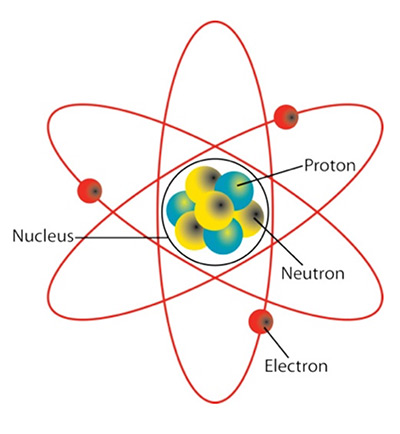

Atom: the building block of matter, composing everything we see and touch. Atoms generally have three types of particles within them. The center of the atom houses the nucleus, which is comprised of a given number of positively charged protons and neutrally charged neutrons. The nucleus is orbited by negatively charged electrons. The different elements in the world are made up of atoms, and each element has a specific atomic arrangement of these particles as shown in the periodic table of elements. Elements and the nature of their atomic composition are the basis of all chemistry and nuclear science.

Atom: the building block of matter, composing everything we see and touch. Atoms generally have three types of particles within them. The center of the atom houses the nucleus, which is comprised of a given number of positively charged protons and neutrally charged neutrons. The nucleus is orbited by negatively charged electrons. The different elements in the world are made up of atoms, and each element has a specific atomic arrangement of these particles as shown in the periodic table of elements. Elements and the nature of their atomic composition are the basis of all chemistry and nuclear science.

The different elements in the world are made up of atoms, and each element has a specific atomic arrangement of these particles as shown in the periodic table of elements. Elements and the nature of their atomic composition are the basis of all chemistry and nuclear science.

Radioactive decay: the process in which an unstable atom spontaneously emits radiation in the form of atomic particles or energy. Any substance that naturally undergoes radioactive decay is considered to be “radioactive.”

Isotope: an unstable variant of an element, usually as a result of radioactive decay and/or something called transmutation (explained next). Isotopes have numerical designations reflective of their atomic composition. For example: uranium-233 and uranium-235 are isotopes of the element uranium.

Transmutation: the process in which one isotope of an element becomes an isotope of another element through nuclear means (like absorbing a neutron).

Fission: the splitting of an atom’s nucleus, releasing tremendous energy and “fission products” (usually radiation + isotopes of other elements). For example: reactors fueled with enriched uranium work by using a neutron to split the nucleus of uranium-235 into kryptonium-92 and barium-141.[25]

Fusion: the joining of atomic nuclei together to form a new element, releasing more energy than even fission. For example: fusing tritium and deuterium (isotopes of hydrogen) into helium, which is how our sun works.[26]

Fissile fuel: an isotope of an element that can undergo fission directly inside a reactor. Uranium-233 and uranium-235 are fissile fuels.

Fertile fuel: an isotope of an element that can’t undergo fission directly, but can if transmuted into a fissile fuel. Thorium is a fertile fuel.

Enrichment: the process of adding greater levels of a radioactive isotope within a nuclear fuel supply. For example: Light Water Reactors use “enriched uranium,” which involves adding more uranium-235 to a fuel supply to sustain fission. Nuclear weapons use “highly enriched” nuclear material to sustain a faster chain reaction. Thorium reactors (especially LFTRs) do not require enrichment.[27]

Breeding: a process in certain reactor designs that employ transmutation to transform a fertile fuel into a fissile fuel. Any reactor that undergoes a breeding process is considered a “breeder reactor.” LFTRs are breeder reactors.[28]

Pressurized Water Reactor (PWR): 1950’s-era reactor designs that use highly pressurized water to help regulate and make possible a fission reaction inside a reactor core. Pressurized Water Reactors use solid fuel and are the most common nuclear reactors operating today.[29]

Light Water Reactor (LWR): a type of Pressurized Water Reactor that uses enriched uranium to generate electricity. Most Pressurized Water Reactors take this form.[30]

Heavy Water Reactor (HWR): a type of Pressurized Water Reactor that does not use enriched uranium, but rather uses a type of water with an extra neutron, known as deuterium oxide or “heavy water,” to sustain fission. These reactors are less common, but still present proliferation risks – especially for weapons-grade plutonium.[31]

Molten Salt Reactor (MSR): a type of advanced reactor design that uses a special type of non-radioactive salt that becomes liquid at high temperatures to act as both a moderator for the reactor and a carrier mechanism for nuclear fuel. They operate at standard atmospheric pressure and have a liquid fuel supply. LFTRs are a highly efficient form of Molten Salt Reactors that also undergo breeding.[32]

With these terms defined, we’ll take a minute to review a bit of our history with atomic energy – specifically addressing why thorium isn’t the primary source of nuclear fuel today.

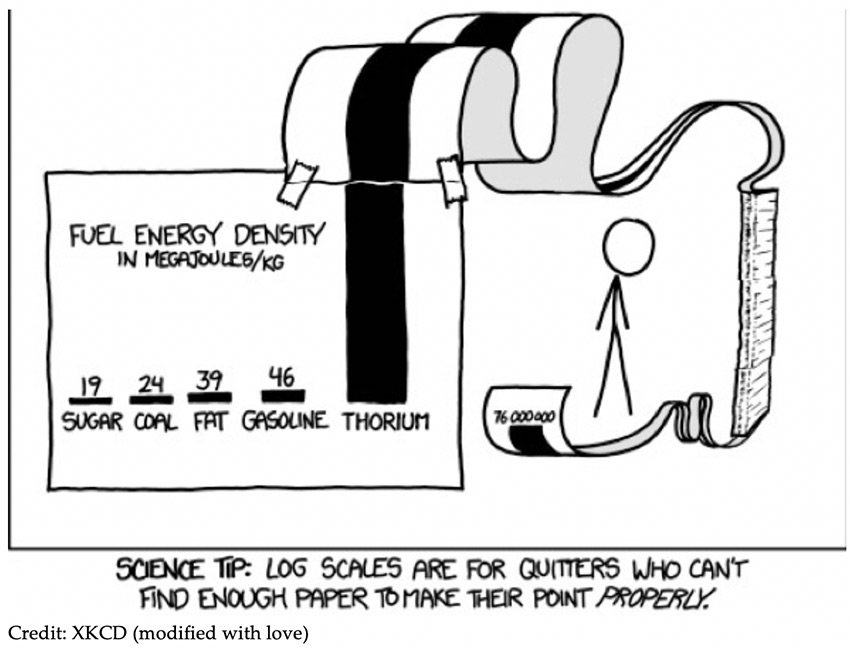

The Unholy Alliance: Electricity and Bombs

Most nuclear reactors, including those within the United States, are fueled by uranium-235, an isotope representing less than 0.7% of all naturally existing uranium on Earth.[33] Uranium-235 is a fissile fuel, meaning that the possibility exists for its atomic nucleus to split into isotopes of other elements if hit by a fast-moving neutron, releasing levels of energy that are millions of times greater than any known chemical fuel source. For reference: burning a single molecule of methane releases 9.6 eV (electron volts) of energy.[34] Fissioning a single uranium-235 atom releases 200 MeV (million electron volts) of energy.[35] That’s a huge difference.

For nuclear fission to work for power generation, it involves a concept known as “criticality”: a threshold, or “critical mass,” where there is enough fissionable material present for the reaction to sustain itself. As it exists in nature, elemental uranium is not capable of doing this. Yet the isotopes uranium-233 and uranium-235 are. If these isotopes are extracted and placed in a controlled environment (or if enriched into a fuel supply) the fission reaction becomes sustainable over long periods of time. Within Pressurized Water Reactors, this reaction efficiently produces heat, which boils water into steam that turns a turbine and generates electricity. In concept, traditional nuclear reactors are just a very efficient and sophisticated implementation of steam power.

But for several reasons, this past approach is less than ideal. For starters, the uranium-235 fuel cycle is more reactive than thorium and harder to control once it reaches criticality. Further, its sustainability as a fuel source is limited, and spent fuel rods must be replaced (along with the reactor core) every 18-24 months[36] – requiring reactor shutdown. As spent fuel is highly radioactive and contaminates anything it comes in contact with (including disposal equipment), this process creates an effectively endless supply of radioactive waste. If that wasn’t enough, Pressurized Water Reactors can present extremely dangerous conditions if any part of the reaction became unstable or uncontrollable.

Pressurized Water Reactors were invented in the 1950’s and their designs have remained conceptually consistent since then. Most work just fine. Yet should key systems fail, the uranium-235 fuel supply (which is normally placed in extractible rods)[37] could remain stuck inside the reactor. Should this happen, the reaction would continue unrestrained, generating enough heat to melt the fuel supply and cause it to pool at the bottom of the reactor’s pressurized water core. In this circumstance, the reaction would accelerate exponentially to amplify heat production and water pressure until it eventually caused a steam explosion – resulting in the spread of highly radioactive material over a region. That event is called a “meltdown” and is effectively what happened in Chernobyl.[38] Needless to say, such events are catastrophic beyond hyperbole.

Because of the risk of meltdowns, however unlikely, Pressurized Water Reactors must be built with extensive safety features: containment domes of steel-reinforced concrete that are several feet thick, massive cooling and pressurization apparatuses, and redundant mechanisms that engage in case any systems were to fail. Pressurized Water Reactors also must be built in sparsely populated areas with large buffer zones in case the surrounding region needed to be evacuated in an emergency. The expenses and security concerns of this reality prompt an important question, though: why in the heck are we using uranium-235 within Pressurized Water Reactors, even though better alternatives exist?

Simply stated? Because at the end of the day, the uranium-235 fuel cycle is mankind’s best-known pathway to building nuclear weapons.

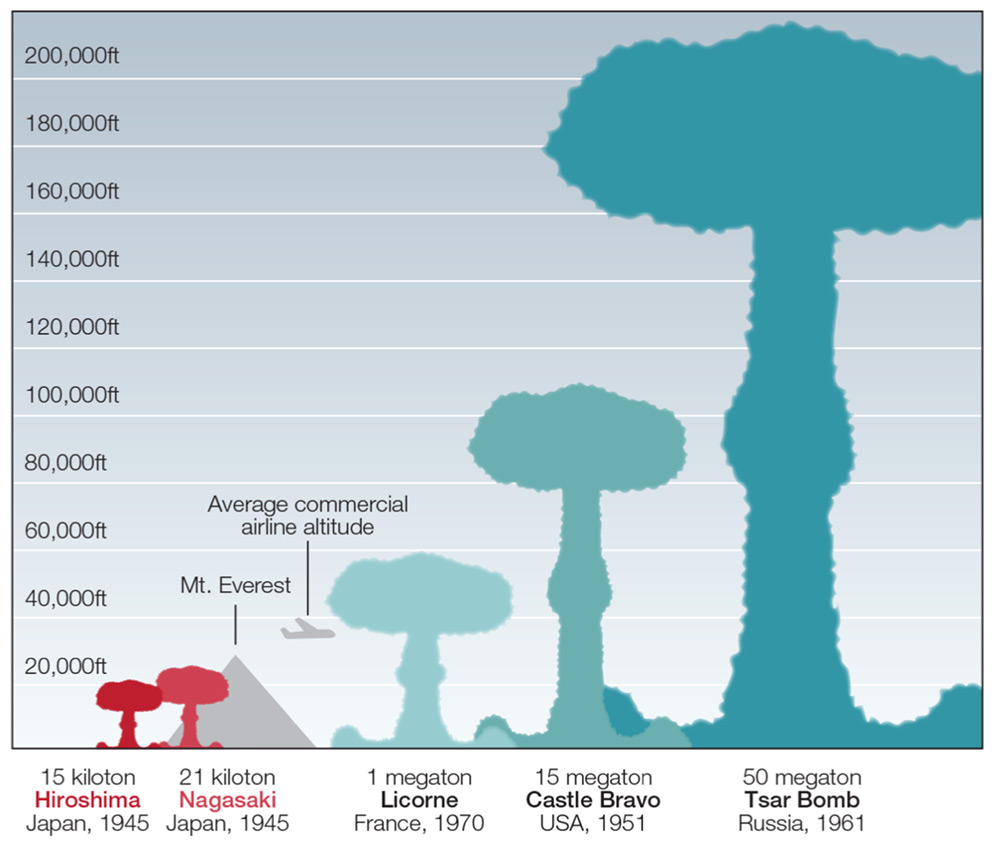

During World War II, scientists working for the U.S. government (and Third Reich)[39] discovered that certain fissile isotopes had a unique property: if enriched highly enough, they could reach a super-critical state. And if, in this super-critical state, they were rapidly bombarded with neutrons, it could create a nuclear detonation – resulting in the most powerful man-made force in existence.

As it was two of those detonations that ended World War II, the significance of atomic weaponry could not be downplayed, especially once the Cold War unfolded. Thus, as civilian nuclear power developed as an energy source, so did the development of nuclear arms and their delivery mechanisms. These two sectors converged to ensure our continued use of uranium-235 as fuel.[40] But not just because its highly enriched forms are far more powerful than conventional explosives in weapons of war. The other, more essential reason is that the uranium-235 fuel cycle can be leveraged to artificially create plutonium-239 – a far more potent weapons fuel that does not naturally exist on Earth in any significant quantity.[41]

And you need plutonium-239 to build hydrogen bombs.

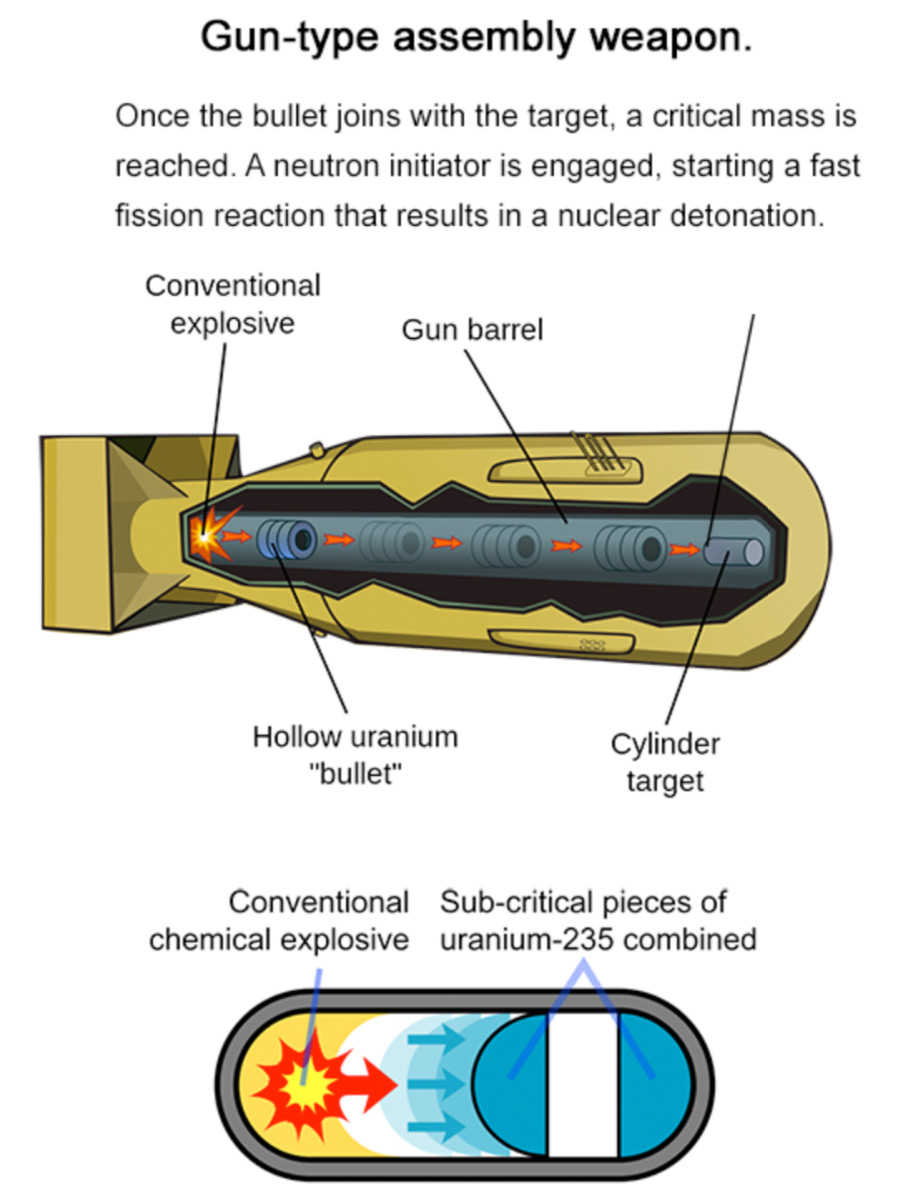

Nuclear bombs come in varied shapes and sizes. With the right materials, building a basic nuclear weapon is, in theory, relatively straightforward. The general idea is to:

- Find a way to rapidly combine highly enriched fissile material together into a critical mass (explosives usually do the trick),

- Introduce a high-intensity neutron source to spark a fast-fissile chain-reaction, and

- Tada! – you’ve got yourself a nuclear bomb. (Please don’t actually try this at home).

The following image shows a nuclear weapon similar to the description above – a gun-type assembly weapon, which is the bomb the United States dropped on Hiroshima. It’s fairly simple, conceptually speaking.

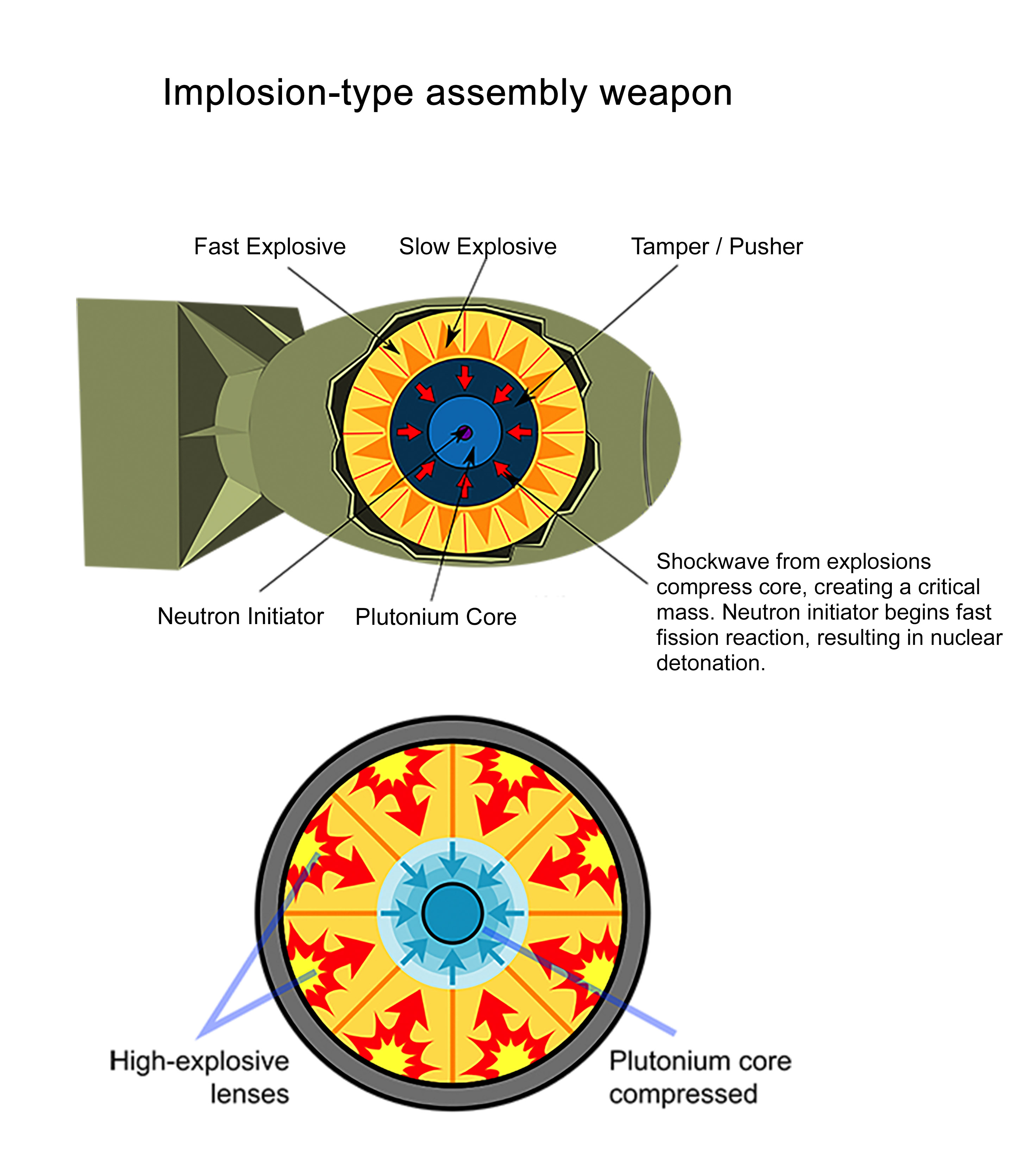

However, building a powerful bomb that’s still compact enough to function as a missile’s warhead requires an implosion-type assembly. This method delivers a critical mass through implosion – compressing a larger sphere of fissile fuel into a smaller sphere by means of explosives – a highly sophisticated and difficult process. Implosion-type devices can not only be significantly smaller than gun-type devices, they are also far more efficient and thus far more destructive.

Uranium-235 isn’t very effective in implosion-type devices, as it has a high critical mass requirement – complicating its deployability in military conflict.[44] Plutonium-239, on the other hand, has a much lower critical mass requirement,[45] but only exists in trace amounts on Earth.

Yet the fuel and reprocessing cycles within Light and Heavy Water Reactors provided a convenient method to source plutonium-239 for implosion devices.[46] As these devices can be built small in size (basketball or smaller), this led to future weapons designs that leveraged their immense energy to fuse isotopes of hydrogen together, providing a dramatically more powerful explosion. Thus, the hydrogen bomb was born,[47] as was our reliance on uranium-235 to source the plutonium that makes them possible.

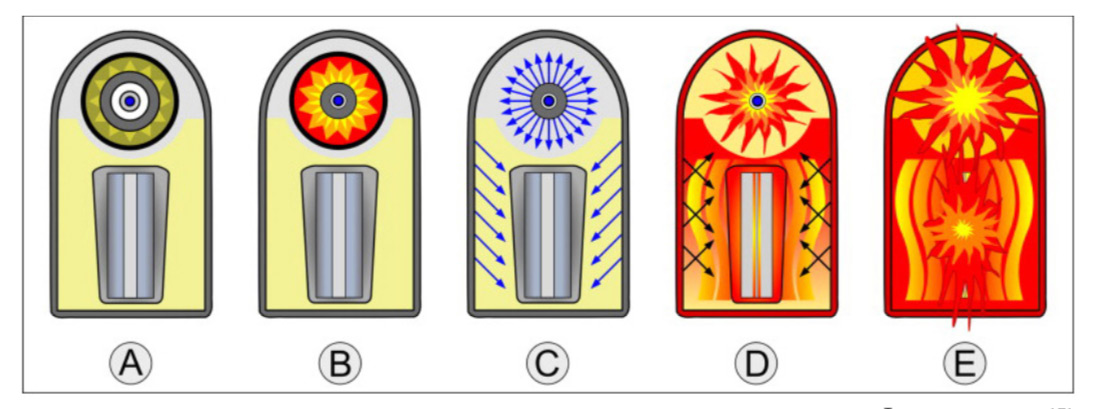

The following image shows the basic stages of the thermonuclear detonation of a hydrogen bomb, employing a Teller-Ulam design:[48]

B): The bomb is triggered. The high explosive charges of the primary activate and compress the plutonium core into a super-critical state. A fission detonation occurs.

C). Within the first nanoseconds of detonation, the fission primary emits high levels of X-ray energy that reflect inside of the bomb case. This irradiates the polystyrene foam.

D). The heat and X-ray irradiation cause the polystyrene foam to turn into superheated plasma, which expands massively and compresses the secondary. As this occurs, the excess neutrons from the primary’s fission reaction cause the plutonium in the secondary’s sparkplug to undergo fission, creating even more heat, pressure and radiation.

E). At such extreme heat and pressure, the lithium-6 deuteride separates into tritium and deuterium, which are isotopes of hydrogen. Under these circumstances, these isotopes fuse together to form helium in a reaction thousands of times more powerful than the fission detonations of atomic bombs.

In short: by harnessing the heat, radiation and pressure of an implosion-type fission bomb, thermonuclear weapons fuse isotopes of hydrogen together to create helium, essentially forming a second sun when detonated. With potential yields in the megatons, we can now build weapons that make the bombs dropped on Japan seem like firecrackers in comparison.

But without plutonium-239 to facilitate a thermonuclear detonation, none of the thousands of hydrogen bombs in the world could exist. And without using Pressurized Water Reactors, there would not be a straightforward way to efficiently produce plutonium-239.

This is why we fuel our power plants today with nuclear dynamite that creates waste products that last for thousands of years and rank among the most toxic substances in existence: to build and maintain nuclear arsenals. That’s the dirty secret behind our approach to nuclear energy. We have corrupted the most powerful energy source that we have ever discovered in the name of an arms race, and at the cost of a world placed in perpetual jeopardy.

If we’re willing to contend with the 15,000 nuclear weapons in global arsenals as enough, and finally forsake the drive to intertwine their production with civilian nuclear energy, thorium gives us another option. One that can avoid nearly every complication with past approaches to atomic power, as well as usher in a clean energy future that exceeds every threshold of our present limitations.

Thorium to The Rescue

Although the name “thorium” comes from the Norse god of thunder, thorium isn’t as reactive as its namesake suggests, ranking among the least reactive radioactive elements.[51] It is safe to handle in its raw form so long as it’s not ingested, and by itself isn’t particularly remarkable. This lack of natural reactivity and radioactivity, however, is what makes it an ideal fuel in next-generation reactor designs.

As a LFTR is a type of Molten Salt Reactor (MSR), it powers nuclear fission at normal atmospheric pressure through a wholly liquid core that is self-regulating – a completely different setup from the solid fuel rods and pressurized water cores used in traditional nuclear reactors. As discussed previously, meltdowns are problems with solid fuel reactors because a runaway reaction can’t be controlled, which leads to catastrophic results because the solid fuel melts and creates ever-greater pressure until it eventually causes a steam explosion.[52] But an MSR is designed to operate in “meltdown” conditions naturally. In the case of a LFTR, it’s one of the few circumstances in which thorium is sufficiently reactive – and even then, it’s a slow and steady reaction.

Compare LFTRs and Pressurized Water Reactors to the fable of the tortoise and the hare, and you’re on the right track.

The reaction works like this: thorium-232 and uranium-233 – the kind of uranium that's difficult to use in bombs – are dissolved into molten salts (usually lithium fluoride – but could be any number of alternatives)[54] and fed into the reactor. The molten salts act as a carrier for the thorium fuel and as a catalyst for the reaction, which keeps the fuel supply at high temperature and at the same time helps refuel the reactor over time through breeding.[55]

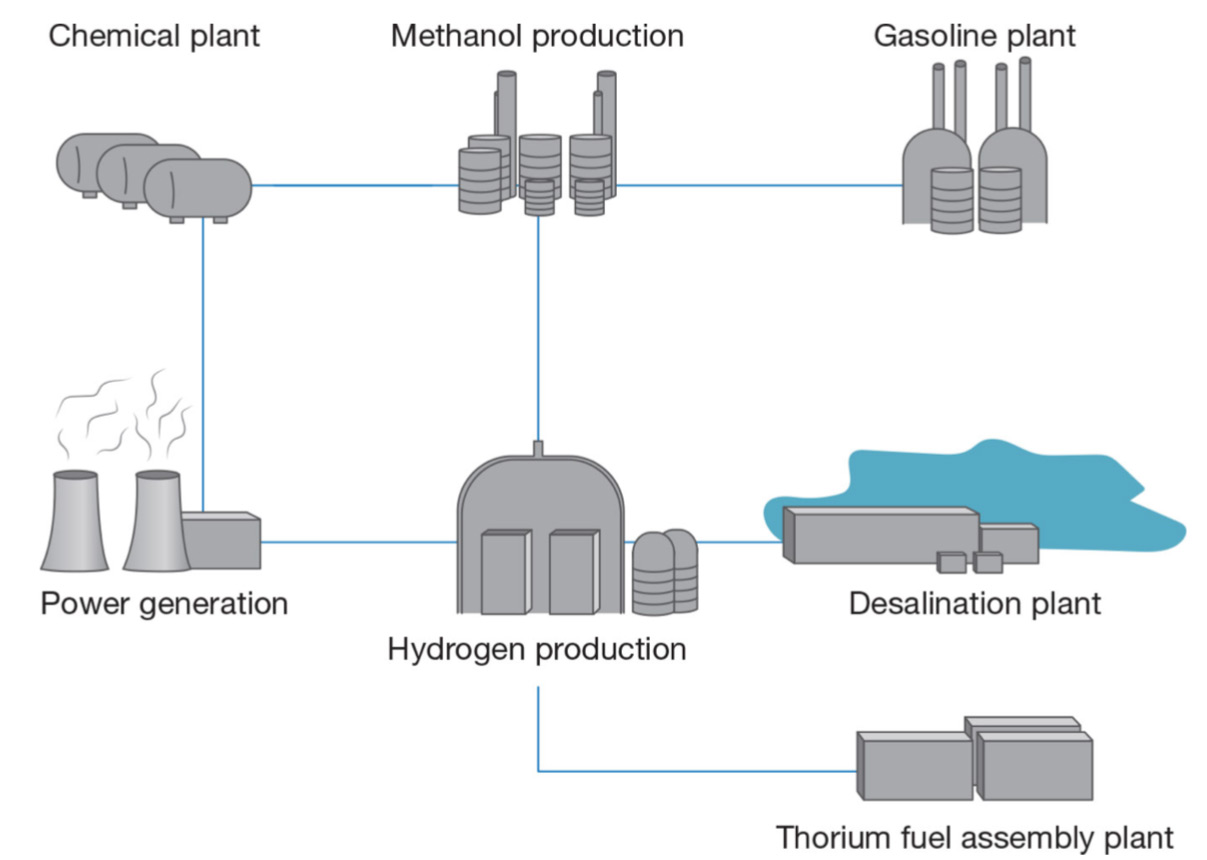

More technically, a LFTR’s core fissions uranium-233, releasing heat, energy and excess neutrons that combine with the fertile thorium-232 in the liquid molten salt to form more fissile uranium-233 through transmutation. Then, the newly-transmuted uranium-233 is fed back into the reactor core, making for sustained, efficient, and self-regulating fission.[57] This fission reaction, through a series of heat exchangers, then heats an inert gas that is sent through turbines to generate electricity. As this reaction generates lots of heat, there remains plenty of leftover energy that can also be used for on-site water desalination and hydrogen production, which we’ll discuss in the next few chapters.

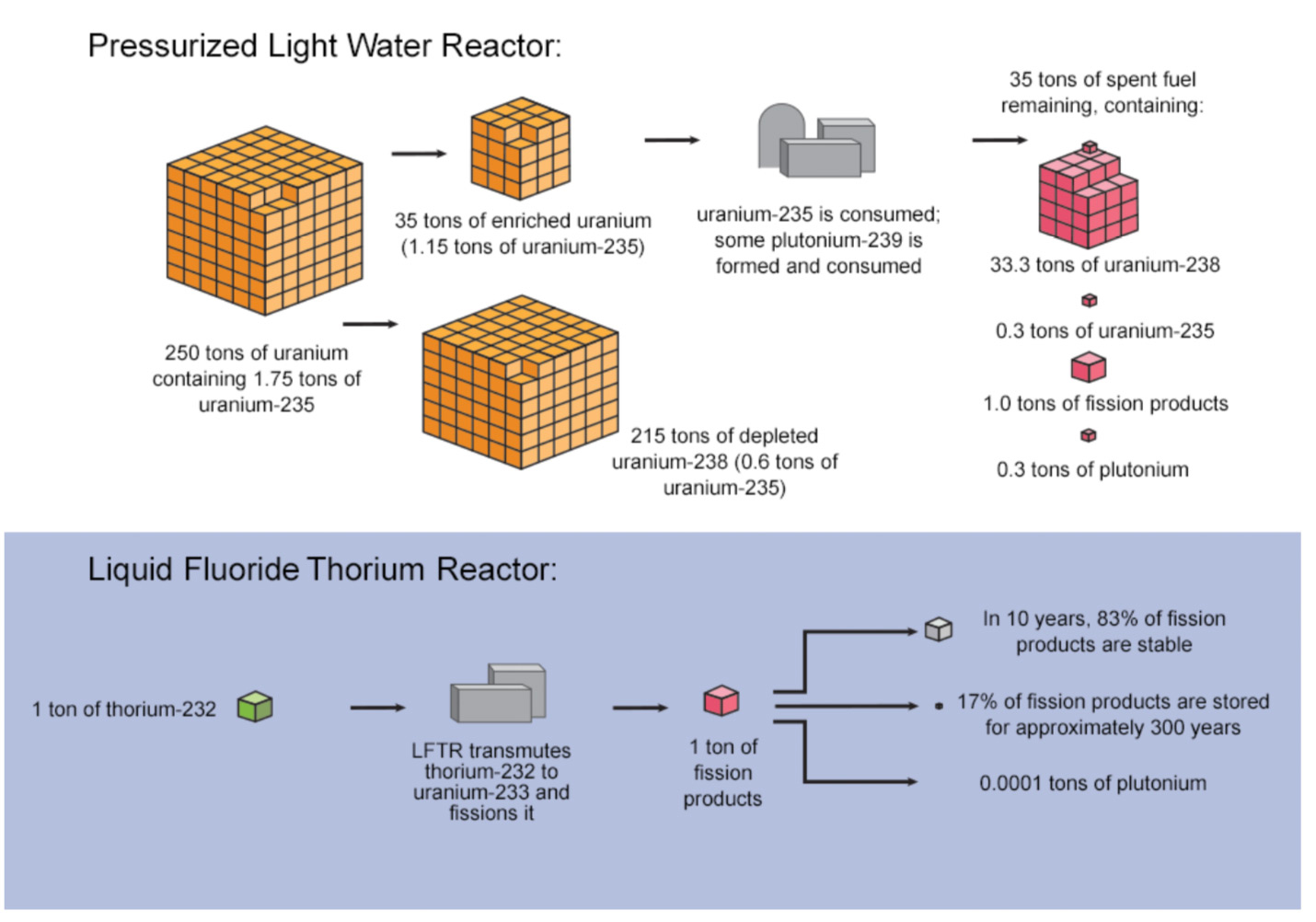

As LFTRs can reprocess and resupply their own fuel from the waste products of the original fission reaction, in addition to a hefty supply of fertile thorium (known as the “blanket”), LFTRs essentially refuel themselves for long periods of time at high efficiencies. Just how efficient are LFTRs? One ton of thorium-232 in a LFTR gives us the energy equivalent of 250 tons of uranium-235 in a traditional Light Water Reactor, or 4.16 million tons of coal in a coal-power plant.[58]

The breeding process can allow the reactor to continually reprocess and produce its own fuel from thorium for up to 30 years without replacement (although this time would be likely be shorter due to the eventual need to replace certain components of the reactor core).[59] For a fuel supply, though, that’s still some 15 times longer than traditional Light Water Reactors.[60] Plus, LFTRs are 54% efficient (some 20% higher than most coal plants) and use 99% of their fuel.[61] And as that 46% efficiency loss primarily takes the form of heat, we can re-capture that heat to power auxiliary systems that produce resources.

The use of thorium-232 in LFTRs is superior to the use of uranium-235 in a Pressurized Water Reactor in other ways as well, particularly when looking at safety, sustainability, scalability, security and cost.

Safety. Because LFTRs operate at normal atmospheric pressure, far less can go wrong. And in case of emergencies, the fix is simple and effective: gravity. As the reactant is liquid, it can drain into smaller storage tanks with insufficient critical mass to sustain the reaction, thus it freezes.[62] This makes it physically impossible for a LFTR to “melt down” in the traditional sense, even under catastrophic circumstances.[63] If a LFTR was targeted by terrorist attacks and blown up, the liquid reactant would flash-freeze into a solid once exposed to the open air. Additionally, once its fuel cycle has completed, LFTRs produce substantially less radioactive waste than Pressurized Water Reactors.[64] The radioactive waste that remains is also short-lived – staying dangerous only for decades as opposed to millennia.[65]

Thorium is plentiful and sustainable for long-term use. About as common as lead, the global supply of thorium is three to four times greater than all forms of uranium – and only 0.7% of all uranium is fissile.[66] Thorium is also a common byproduct of rare earth metal mining, presenting straightforward opportunities in the short-term for easier acquisition.[67] There is enough thorium in the United States alone to power the country for the next 10,000 years.[68]

LFTRs have a greatly reduced environmental footprint. By nature of their operation, most radioactive waste inside LFTR cores is consumed by the reactor.[69] This enables LFTRs to consume other types of waste as well, including weapons-grade fissile material and even the nuclear waste generated by traditional nuclear reactors.[70] In turn, LFTRs can then act as nuclear garbage disposals that also generate electricity for decades.[71] The physical amount of waste remaining once the reaction consumes all fuel is less than 1/1000th of the waste produced by Light Water Reactors.[72] Additionally, LFTR waste decays quickly, with the most toxic radioactive isotopes having a half-life of only 30.17 years.[73] This means that a supply of radioactive waste from a LFTR would become less radioactive than natural uranium within a period of 300 years or less.[74] More toxic radioactive waste from Light Water Reactors can last for thousands of years.[75]

LFTRs reduce the possibility of proliferation. The weaponization of a nuclear reaction is unique in that only uranium-235 and plutonium-239 have been known to make a militarily effective bomb. However, while not on the same scale it is technically possible to create a rudimentary nuclear device using material produced in LFTRs – namely through uranium-233 and neptunium-237.

Yet doing so is considerably more difficult and less reliable than with traditional nuclear materials and traditional nuclear reactor designs. Further, uranium-233 and neptunium-237 – even if fashioned into a nuclear weapon – would likely make the device ineffective for military purposes. The reasons?

Purification difficulties and inherent dangers. It's been theorized that if an LFTR is using something called a fluorinator, neptunium-237 can be extracted via a chemical process, which has potential to undergo a fast-fissile reaction and enable a nuclear detonation.[76] But the critical mass requirement for neptunium-237 is roughly 60 kilograms, which is higher than even uranium-235 – and emits 2,000% more gamma emissions than plutonium-239.[77] That would make such a weapon far more dangerous to build and less practical to deploy even if the expertise to weaponize neptunium-237 existed.[78] Further, chemical purification to this degree requires highly expensive and purpose-built infrastructure that can’t be obtained by entities other than states with sophisticated science programs.

Moreover, part of the breeding process to transmute thorium-232 into uranium-233 involves the production[79] of an invariable amount of uranium-232 – which, while perfectly safe within a reactor, also emits high levels of both alpha[80] and gamma radiation.[81] For those inclined, ionizing radiation (the potentially harmful kind) is commonly measured in “rem” (Roentgen Equivalent Man).82/cite] In general, the more radiation one absorbs, the more harmful the effects become. At standard levels, the uranium-232 contaminant within a 5kg sphere of uranium-233 would generate up to 38 rem per hour.[83] For use in a weapon, uranium-233 has a minimum critical mass of 16.5 kilograms[84] - presenting an aggregate dose of up to 125 rem/hr. Serious radiation sickness begins with short-term exposure of 150 rem, and anything over that is potentially lethal.[85]

At sufficient mass to build a nuclear weapon, this would make the material too dangerous to handle by human beings and would require the employment of sophisticated (and expensive) remote-assembly robotics – traits not shared by other weapons-grade nuclear material.[86] Additionally, uranium-232’s gamma emissions damage sensitive electronics and increase material heat,[87] which can prevent a sophisticated nuclear device from detonating under precise and exact conditions – hard requirements for effective use as a weapon.[88]

These are important distinctions in light of concerns from nuclear agencies that cast aspersions on thorium’s proliferation resistance. One notable example of these concerns comes from a 2010-era report by the United Kingdom’s National Nuclear Laboratory[89] that states:

As with neptunium-237, “proliferation risk” is contextual – and much of that context derives basis from academic postulation as opposed to tangible capability. Just because a state could theoretically make a nuclear device from uranium-233 doesn’t mean it can make one practically – all the more so since there is negligible data or expertise to aid in the creation of such a device. And even if that effort was successful, none of that says such a device would be sufficiently powerful for use in a conflict – or even if it can be effectively deployed in the first place.

Once those factors enter the equation, the optics change significantly.

The UK National Nuclear Laboratory is, of course, correct. Both uranium-233 and neptunium-237 are fissile fuels, and both have potential to undergo nuclear detonations.[90] Further, the uranium-232 contaminant within uranium-233 probably wouldn’t stop a crude bomb from detonating crudely even if it killed its makers.

But it would stop a bomb that relies on sophisticated technology to implode in the precise detonations required for miniaturization to a warhead-scale. It also ignores that LFTRs can be designed to minimize the risk of weaponization barring major infrastructural investments that would draw the attention of international atomic energy monitors. And even if a state had enough neptunium-237, the critical mass requirements would hinder the ability to deploy a weapon of sufficient yield unless that weapon was carried by aircraft or large, long-range missile. The presence of both of these factors would remove either isotope from consideration as a primary charge for a thermonuclear device, and would further preclude both from use as a first-strike weapon.[91]

Further, even if we did grant credence to a rouge state’s ability to invest the time, effort, and risk to either purify uranium-233 or build a weapon with neptunium-237, it’s important to emphasize just how difficult this is to do – all the more so to do so quietly. If any rogue nation tried to build such infrastructure, any intelligence agency with a satellite would know exactly what was going on in short time (which is how we know Iran, North Korea, etc., have nuclear weapons programs).

Nuclear weapons design isn’t secret anymore – no 75-year old technology is. The hydrogen bomb, even, is old enough to collect social security. But reaching certain milestones towards making one are only possible with highly expensive and sophisticated systems built specifically for that purpose. They’re not the sort of thing one picks up at Walmart, and their procurement would certainly raise flags among international monitors and foreign intelligence services – especially since there’s only a few entities in the world that manufacture them. If that wasn’t enough, they remain among the most controlled machines on the planet.

If your life’s ever lacking excitement, try wiring a few million dollars to an offshore bank account for an order of krytron tubes, ultra-fast relay switches, large gas centrifuges and a hefty supply of lithium-6. At the very least you’ll see a whole lot of government property and personnel you didn’t know existed appear awfully fast. Should any state try the same, that property and personnel usually manifests in the form of an airstrike to destroy such a program in its infancy. That’s usually long-before said state has even conducted the multitude of tests needed to see if their bomb design even works, as (likely) happened in Syria in 2007.[92]

At the levels of sophistication and expertise required to covertly obtain the necessary materials and successfully make a bomb out of uranium-233 or neptunium-237, building a bomb with traditional nuclear materials sourced from the ground or ocean[93] becomes an easier prospect.

Even so, commercial LFTR designs would need to be required to intentionally contaminate the reactant with materials that would make weaponization harder from the start.[94] This wouldn’t permanently remove the risk, but it would make it much more difficult for all but the most dedicated actors. In those cases, if a state is advanced enough to make a nuclear weapon from thorium, they don’t need thorium to make one in the first place.

And regardless, it’s still poor bomb fuel. Even if they could be efficiently extracted, uranium-233 and neptunium-237 are ineffective fast-reacting fissile fuels compared to highly enriched uranium-235 and plutonium-239. There are only two known nuclear weapon tests that have ever used uranium-233 – none have ever used neptunium-237. Both of the uranium-233 devices were largely considered failures due to weaker-than-intended explosive yields, respectively at 22 kilotons (U.S. – 1955) and 0.2 kilotons (India, 1998) – relative pittances compared to modern nuclear weapons.[95] In the first device, the uranium-233 was chemically purified (which, again, is highly difficult to do) and was significantly complemented by plutonium-239 to increase yield.[96] As a consequence of those lackluster tests, there exists little research or expertise to weaponize uranium-233 or neptunium-237, nor avoid the inherent dangers of doing so.[97]

And even if there was research or expertise, what’s the endgame? To bring dynamite to a thermonuclear missile fight? In a realpolitik sense, the leverage gained by building a nuclear weapon is only as valuable as its effective usability in a conflict – or a hedge against the same. A single U.S. Navy Ohio-class submarine can launch 24 missiles – each armed with up to 12 thermonuclear warheads that each yield 475 kilotons – and the U.S. Navy has fourteen of such submarines. Nothing from thorium is ever going to produce anything that can hold a candle to that.

This is why every state with nuclear ambitions has instead invested in uranium-235 and plutonium-239, for their use is easier and safer than hijacking the thorium fuel cycle to produce weapons-grade material. While again, this does not totally alleviate concerns of proliferation through thorium, it does reduce them to a significance on par with a state making an in-house weapons program of their own volition – and that’s becoming increasingly more plausible as technology advances globally. With these considerations in mind, the clean energy benefits that thorium and LFTRs bring simply outweigh the theoretical risks of either being used by a dedicated actor for nefarious purposes.

LFTRs are simpler, smaller and less expensive than Pressurized Water Reactors. As traditional nuclear reactors have to be pressurized to 160 atmospheres just to function – pressure equal to a mile below the ocean’s surface[98] – they require redundant processes and complex systems to manage the reaction and ensure nothing goes wrong. Additionally, as Pressurized Water Reactors present the potential for catastrophic environmental damage should a reactor melt down or be destroyed through sabotage, they further require extensive security infrastructure. Combined, these factors cause such reactors to rank among the most expensive and over-engineered systems on the planet:

| Light Water Reactor fueled by uranium-235 | Liquid Fluoride Thorium Molten Salt Reactor (LFTR) |

|---|---|

| Fuel: Uranium-dioxide solid fuel rods | Fuel: Uranium-233 and thorium-232 in a solution of molten lithium-fluoride salts |

| Fuel lifetime: Two years at best. Requires reactor shutdown to replace. Core + fuel rods remain radioactively contaminated | Fuel lifetime: 30 years without replacement. Current graphite core lifetime is in excess of six years |

| Fuel input per gigawatt output: 250 tons uranium-235 | Fuel input per gigawatt output: 1 ton thorium-232. 250 times more efficient |

| Annual fuel cost for 1-GW reactor: $60 million | Annual fuel cost for 1-GW reactor: $10,000 (estimated) |

| Total unit construction cost: $7.0 billion | Total unit construction cost: $1.0 billion* (1-GW reactor) |

| Coolant: Highly pressurized water with a graphite moderator | Coolant: Self-regulating with passive gravity emergency shutdown |

| Weaponization potential: High | Weaponization potential: Low |

| Physical footprint: 300,000 square feet + large buffer zone | Physical footprint: 2,000-3,000 square feet (size of a house). No buffer zone required |

As LFTRs are spared the size, expense and security requirements of Light Water Reactors, they can be built much smaller and less expensively. They can also be built closer to population centers (as opposed to Pressurized Water Reactors that need to be geographically isolated), considerably reducing the infrastructural requirements to transmit power to electric grids.

LFTRs can be built in a modular, prefabricated capacity. Today’s nuclear reactors are designed as unique, custom systems that are each made to order – significantly increasing their total cost. Yet recent improvements in manufacturing today allow LFTRs to be built on assembly lines as iterations of product models in the form of small modular reactors.

This provides two main benefits:

First, efficiencies inherent in modern manufacturing enable us to reduce construction costs over time as more identical units are produced. This is often referred to as “the learning curve,” or “learning ratio” – the reduction in manufacturing cost every time the number of produced units doubles.[101]

In computing, Moore’s law has shown that computer processing power at a given price doubles every two years. In aerospace manufacturing, the reduction in per-unit cost has been roughly 20% every time the number of produced units has doubled.[102] As applicable to the manufacturing of Light Water Reactors, the University of Chicago estimates a learning ratio of 10% in their 2004 study The Economic Future of Nuclear Power.[103] As LFTRs can be built on assembly lines, that percentage would likely be higher, expected to be on the order of aerospace-grade manufacturing.

But even at 10%, this would mean that by the time the 1,000th LFTR was constructed it would cost around 40% of the first commercially produced unit. This means that if the estimated price tag for a LFTR stands at $200 million currently, as more units were produced that cost would fall over time – making them increasingly more affordable and economically viable. The following except is from Thorium: Energy Cheaper than Coal, written by Robert Hargreaves, PhD, Professor of Nuclear Physics at Dartmouth University:

The second main benefit of manufacturing LFTRs on an assembly line is standardization, and standardization provides modularity. This becomes important when building small modular reactors because not only are smaller, modular and standardized reactors considerably less expensive to construct, they are also easier to deploy.

If you recall, a core requirement of Scarcity Zero is widespread deployment, as many regions that suffer from the consequences of resource scarcity are geographically remote and/or feature terrain that’s hostile to the construction of something as large as a power plant. A smaller LFTR manufactured on an assembly line can be built rapidly and plugged into any grid in a relatively short time period.

So if, for example, a region needed to quintuple its electricity generation capacity in a matter of weeks, small modular LFTRs make this possible – and they make this possible effectively anywhere. This also would pay dividends toward disaster-relief efforts, peacekeeping missions, ocean trash cleanup and possibly even space exploration.

How We Know It Works

The thorium fuel cycle has been known to science from the start of the atomic era, and reactor designs associated with that cycle have been around since the 1950s. The first successful use of thorium came from the Department of Energy’s MSRE experiment, a 1960’s-era project from the Oak Ridge National Laboratory working from prior research to build a molten salt reactor for aircraft propulsion.[104] The 7.4 Megawatt reactor went online in 1965 and worked successfully for four years until the experiment was cancelled in 1969 in favor of Light Water Reactors.[105] Light Water Reactors eventually became the national standard largely because they could produce both energy and weapons-grade radioactive isotopes.[106]

While that unfortunate result isn’t particularly surprising, the results of the MSRE experiment nonetheless conclusively showed that the reactor concept was viable,[107] as have other tests since. The MSRE experiment confirmed predictions and expectations, showing the safety, efficiency and heat transfer potential for LFTRs was present using 1965-era capabilities. Several other countries and companies have since made progress on LFTR technology. Notable high-profile projects include:

China: The Chinese government has invested $3.3 Billion into molten salt reactors in Gansu province under the name “Thorium-Breeding Molten Salt Reactor (TMSR).”[108] These reactors are being built underground, and are intended to generate up to 100 megawatts of power. Their reactor models heavily leverage cogenerative design, using excess energy to power other resource-producing systems including fresh water, hydrogen and hydrocarbon fuels.[109]

Although a large focus of this project is electricity for civilian usage, the Chinese government hopes to apply the results of this project to military applications like drones and future fast aircraft carriers.[111] As reactor miniaturization would be required for placement within something as small as a drone or warship, such an advance would present significant implications for NATO states in both civilian and military sectors – making a matching investment in LFTR technology all the more pressing. As of this writing, the Chinese program intends to have a functional reactor prototype by 2025 with large-scale commercialization by the early 2030’s.[112]

The Netherlands: The Dutch NRG (Nuclear Research and Consultancy Group) is one of the leading European nuclear service providers. They have constructed a prototype Molten Salt Reactor that began fluoride salt irradiation on August 10th, 2018.[113] Instead of turning a live reactor “critical” for sustained civilian power, the NRG intends to conduct a series of experiments (referred to as SALIENT) to reinforce the validity of thorium energy and use the experiments as templates for future LFTR development.[114]

Unique among other thorium R&D efforts outside of G8 states is the NRG’s installation in Petten, which has all of the decontamination, cleaning, salt production, radiation shielding and fine element analysis equipment to build a nuclear reactor in-house.[115] As a semi-private venture, the NRG can now compete with state-level actors to fine-tune the necessary manufacturing requirements to achieve LFTR viability.

India: A nuclear power since the 1950’s, India is no stranger to the promise, challenges, and risks inherent to atomic energy. Yet among members of the “nuclear club,” India is unique in that it has the largest thorium reserves of any sovereign nation – some 11.5 million metric tons.[116] This has led India to accelerate research and development on thorium-powered molten salt reactors as a part of its three-stage nuclear program.[117]

India’s latest effort is the Kalpakkam prototype fast breeder reactor, designed to generate 500 megawatts of electricity. The Kalpakkam prototype is expected to reach criticality by the early 2020s.[118]

Explaining the benefits of the reactor model to the Times of India, the Director General of the International Atomic Energy Agency noted that “fast reactors can help extract up to 70 percent more energy than traditional reactors and are safer than traditional reactors while reducing long-lived radioactive waste by several fold.” It’s worth noting for our purposes that while fast breeder reactors are akin to LFTRs in both theory and function, and present promising results even in initial prototype stages, the designs have had stability issues in the past and present varied engineering challenges to long-term stability.[119]

For this reason, India has been running a forerunner reactor to the prototype they’re building in Kalpakkam under the Fast-Breeder Test Reactor program. This smaller reactor has had its own technical challenges, yet has reliably produced impressive amounts of energy even while operating at significantly less than total capacity.[120] In doing so, it has provided Indian nuclear scientists with the data needed to complete the larger Kalpakkam reactor – which itself can be used as a stepping stone to further advancement in breeder reactors that leverage the thorium fuel cycle. The third stage of India’s nuclear program is designed to use thorium exclusively.[121]

Russia: while India has nearly completed their prototype fast breeder reactor, Russia has successfully deployed the technology since the early 1980s at the Beloyarsk Nuclear Power Station.[122] The station currently operates two fast breeder reactors – the only two in the world that are currently operational – respectively generating 600 and 885 megawatts each.[123] However, unlike Indian variants, these Russian fast breeder reactors are fueled by enriched uranium, due to plentiful Russian reserves and the security “benefit” of uranium’s dual support of civilian energy and nuclear armament.

Things are changing, however, as Russia is currently developing a high-temperature breeder reactor fueled by thorium, which, like China’s variant, is expected to divert waste heat energy to desalinate seawater and extract hydrogen.[124] This Russian reactor will also be partially fueled by weapons-grade waste material – paying homage to the ability of molten salt reactors to safety generate electricity as a byproduct of armament reduction initiatives.[125] Professor Sergey Bedenko from the School of Nuclear Science & Engineering at Tomsk Polytechnic University and a co-author of a paper[126] on the project had this to say on the benefits of plutonium-processing:

This project also has the benefit of state backing. As of 2016, President Vladimir Putin has directed Russia’s state energy institutes, Rosatom and Kurchatov, to deliver a proposal on how to leverage thorium for next-generation reactors while improving thorium procurement through rare-earth metal extraction.[127] As reactor technology improves with future research and development, we may see more sophisticated Russian LFTRs that can be manufactured at scale.

Germany: As of this writing, Germany has transitioned from nuclear power to a more renewable-focused approach in response to anti-nuclear political pressure.[128] The results have been mixed at best, and Germany still relies heavily on coal to complement the intermittency and unreliability of using renewables for baseload power.[129] Germany once had functional thorium reactors that operated at high efficiencies and output. Although the design wasn’t a Molten Salt Reactor, their THTR-300 high-temperature thorium reactor worked successfully between 1985 and 1989,[130] but was decommissioned in favor of light-water reactors. Despite its higher costs and unique engineering requirements, the experimental THTR-300 reactor proved thorium’s viability as a fuel and presented a rich supply of test data for future high-temperature reactors.

The United States: as the world’s first nuclear power, spearheading the discovery of both fission and fusion, the United States has extensive experience with atomic energy. Nearly all nuclear engineering today is derived from American designs – including reactors fueled by thorium.

Yet most of these reactors were designed with the intent of providing an ample supply of weapons-grade nuclear material alongside a civilian power program, and the United States remains the only nation in the world to deploy a nuclear weapon in an armed conflict. For these reasons, alongside debates over how to dispose of the nuclear waste associated with Pressurized Water Reactors, atomic energy in America faces significant political resistance – even though it generated 60% of our emissions-free power in 2016.[131]

The political mood is changing, however. 2016 saw the first new American nuclear reactor to come online in decades,[132] and that reactor now generates enough energy to power 650,000 homes.[133] Myriad companies, from startups to long-established nuclear engineering firms, are now exploring advances in thorium reactor technology. Several are even investing in “microreactors,” scaled-down modular reactor designs that can be mass-produced on assembly lines. Although some would still use uranium-235, the mass-produced approach is still important for several reasons:

First, it leverages one of the attributes that makes America the world’s wealthiest economy: its ability to build sophisticated systems on a large scale. When it comes to mass-producing cutting-edge technology with minimal room for error, America’s manufacturing prowess shines brightest. This gives the United States perhaps the best advantage when mass-manufacturing modular reactors on assembly lines to a single standard.

Second, the advances made in miniaturizing reactor technology – even if still fueled by uranium-235 – can be extended to miniaturizing LFTR technology in the future, lowering costs, barriers to entry, and barriers to scale.

Third, microreactors can be built small enough to deliver via train, ship, or even truck or aircraft. That enables them to be transported and deployed effectively anywhere – a key goal of Scarcity Zero.

Several companies are proving to be pioneers in this future frontier of nuclear energy, both within and outside of thorium:

- Westinghouse’s eVinci’s microreactor design is factory built, fueled and assembled. It’s also small enough to transport on a truck, and boasts a 0.06 acre footprint with less than 30 days onsite installation.[134] It can match the energy output of up to 380 acres of wind turbines and 79 acres of solar panels.[135] And at zero emissions, the equivalent energy output with diesel would produce 230 million pounds of CO2. It was partially envisioned to power military bases and research stations in frigid climates where wind turbines freeze, sun is scarce and diesel fuel is the only viable source of energy. Westinghouse’s current designs – planned for release in 2024 – estimate constant operation for upwards of ten years without refueling.[136]

- Corvallis, Oregon-based NuScale Power has its own microreactor designs. Their Small Modular Reactor is designed to provide scalable power generation up to 720 megawatts. While based on the light-water model, their modular design eliminates two-thirds of the internal parts of traditional Pressurized Water Reactors and also incorporates a passive auto-shutdown that doesn’t require external power, additional water or operator action. These distinctions present critical advantages over previous reactor designs, not only in terms of safety but also because they avoid the need for the redundant and expensive containment systems.

At a deployment area of 15x82 feet, the containment vessel and reactor core are roughly 5% of the size of a traditional nuclear power plant[137] - small enough to be delivered by rail, barge or truck. To date, the company has secured more than $300 million in funding from the Department of Energy.138/cite] They plan to construct a 12-module Small Modular Reactor plant at the Idaho National Laboratory by 2026,[139] that would provide up to 720 megawatts of emissions-free power.[140]

- General Atomics is a defense contractor specializing in aerospace and nuclear engineering. As a former subsidiary of General Dynamics, it’s been on the front lines of nuclear advancement since its commercialization, with a proven track record of building reliable high-performing reactors. Their latest reactor concept is billed as an “Energy Multiplier Module,” which is a series of modular microreactors that can be deployed together as a unit and buried below ground.[141]

Image Source: General AtomicsGeneral Atomics reactor designs mimic the benefits of LFTRs in function – breeding, automatic operation for up to 30 years, passive non-mechanical safety measures, the ability to consume both nuclear waste and weapons-grade material as fuel and a high-temperature loop that can be used for supplemental resource production. Although the design is still in concept stages, they have received more than $60 million in funding thus far from the Department of Energy, and continue to join other companies domestically and abroad in developing Small Modular Reactors.[142]

- Terrestrial Energy is a joint Canadian-U.S. startup specializing in thorium-fueled molten salt reactors. It has been working alongside the United States Department of Energy and Oak Ridge National Laboratory to bring smaller-scale LFTRs to market.[143] Larger than a microreactor yet significantly smaller than a traditional nuclear power plant, their patented Integral Molten Salt Reactor (IMSR) is modular in design and scalable from 80 to 600 Megawatts on 17 acres or less.[144] As with any LFTR, Terrestrial Energy’s design includes secondary and tertiary heat loops for supplemental resource production. The company is expecting to start their first reactors by the 2020’s with larger-scale commercial viability thereafter.[145]

As designed, each of these modular reactors can be assembled in groups to meet the output of base load power.

The litany of investments in LFTR and other small modular reactor technologies are made because we know these technologies will work, as prototype after prototype has proven it so. We know reactor miniaturization works because we’ve designed and built miniature reactors after thousands of iterations of modeling and tests. We know that standardization and modularity in the design of advanced systems gives way to greater scalability and flexibility in deployment, because we’ve seen these concepts produce this exact effect in every other industry they’ve been employed.

The developed world isn’t investing many billions of dollars into next-generation nuclear technology on a whim, nor would it do so if the science was in doubt. It’s perhaps for this reason why market growth in microreactor technology is increasing at an annual rate of 19%[146] - the investment follows the data, and the data supports the investment.

What About Costs and Criticisms?

It must be mentioned that atomic energy has critics. As is their want, they doubt the technology’s viability on grounds ranging from safety, waste, and proliferation to economic and logistical feasibility. Some see nuclear, in and of itself, as a fundamentally unredeemable technology. Others bring up points that are valid in abstract, yet are used to cast inappropriately generalized aspersions on nuclear’s promise. Thorium, of course, is no exception.

While there are myriad sources that might articulate these criticisms, I’ve chosen three articles for their accessible language and range of arguments. The first two argue against nuclear as a concept, and the third argues against thorium specifically.

I invite you to review them individually, in full, so that you understand where they’re coming from in their own words.

The first article is a February 2019 piece in ThinkProgress entitled “Taxpayers should not fund Bill Gates’ nuclear albatross,” which casts doubt on Bill Gates’ effort to address climate change by increasing nuclear’s American market share.[147][147] The author, Joe Romm, writes:

The second article is from Popular Mechanics, entitled “The Alexandria Ocasio-Cortez 'Green New Deal' Wants to Get Rid of Nuclear Power. That's a Great Idea.”[148] The author, Avery Thompson, had this to say:

Lastly, there’s the thorium-specific criticism written in The Guardian nearly a decade ago.[149] In June 2011, Eifion Rees, an ecologist who advocates for a post-industrial “ecolocracy” (his words), wrote a piece titled “Don't believe the spin on thorium being a greener nuclear option.” In summary, Rees makes the case that thorium is merely a way to deflect attention from the dangers of the uranium fuel cycle within Pressurized Water Reactors that would still be used until thorium had proven large-scale commercial viability.

He states that the nuclear industry itself remains skeptical of thorium and cites the 2010 paper from the UK’s National Nuclear Laboratory[150] mentioned earlier in support. Rees continues that that even if LFTR waste is much shorter lived, it will still be toxic and emit harmful radiation. Rees’s final point is that the effectiveness of renewables is rapidly improving, so even if thorium proves itself in the next 30 years (by Rees’ assessed timeline), it will arrive to solve a problem that’s no longer present. He concludes that the combination of these factors make thorium too new, too untrusted, too potentially dangerous, and too expensive when we already have an energy solution – renewables – in hand.

These articles and mindsets were cited verbatim because I believe in intellectual honesty. They were also cited because they’re wrong. Not just on the facts when it comes to 2020-era technology, but also just as importantly on the role of nuclear in the context of the energy, resource and ecological requirements of our time.

To explain why, we’ll boil down the primary arguments of these three pieces (and the NNL assessment[151] cited in The Guardian) into three overarching criticisms that we’ll review in order.

- Nuclear energy is too expensive in terms of cost and safety, and always will be, thus we should focus exclusively on renewables.

- Thorium’s an unproven technology with unproven viability, thus we should focus exclusively on renewables.

- Thorium advocates overstate its waste and proliferation benefits, thus we should focus exclusively on renewables.

Criticism: Expense

Nuclear power is sophisticated technology, and sophisticated technology costs money. This feeds into a common narrative from nuclear detractors that atomic energy is cost-prohibitive. If waste and proliferation concerns weren’t enough, they say, there’s simply too many expenses behind nuclear engineering, deployment, operation and safety to make the technology viable.

Some of these concerns have merit in abstract. But they don’t necessarily apply to nuclear as a technology any more than concerns about burning zeppelins apply to aircraft as a technology. Further, nearly all focus on Pressurized Water Reactors and point to their drawbacks as cause to paint the entire field of atomic science with a wide brush.

The reason why this chapter focused on smaller LFTRs and made repeated mention of small modular reactors (even if powered by uranium-235) is because they avoid these problems, particularly cost criticisms, by design. Large-scale Pressurized Water Reactors further present major safety hazards if things go wrong, especially as they increase in size. They need massive containment and cooling apparatuses, redundant safety mechanisms, security features, buffer zones and control systems. These highly expensive components are not necessary for LFTR and newer small modular reactor designs. That alone is a differentiating cost factor on the scale of billions of dollars.

Then there’s the fact that most every power plant in America today – nuclear especially – is built as a unique entity, designed and deployed to order. The plant’s concrete, metal, wiring, HVAC, control systems, thermal management, waste processing, plumbing, walkways, stairwells, doors and all points in between are designed, architected and engineered from the ground up each and every time – as is the regulatory approval for each specific building site.

For every nuclear power plant thus far built, a company gathered an architect, structural engineer, nuclear engineer, electrical engineer, environmental engineer, fluid engineer and mechanical engineer to design the plant. Then they hired the contractors to build it, the banks to fund it, the insurance companies to underwrite it, the bond companies to back it, the lawyers to sign off on it and the regulators to approve it. And if they wanted to build another, they then had to wipe the slate clean and do it all over again from scratch because the math and materials that worked for plant A didn’t work for plant B.

It’s no wonder, then, how a nuclear plant can cost billions to construct today. Any system of any level of sophistication would cost the same under those circumstances. If your car had to be built this way, it would cost several million dollars. If a commercial aircraft had to be built this way, it, too, would cost several billion dollars. Automated manufacturing changes this, as it does in any other sophisticated industry. It started with Ford’s assembly line and now works to build jetliners. Once we apply automated manufacturing to nuclear, the same cost effectiveness will be achieved as it has in literally every other industry automated manufacturing has been employed.

Another major additional cost contributor is inappropriate regulation. Nuclear power carries a requisite responsibility of standards and demonstrated operational expertise to develop at scale, and regulations are of course critical to appropriately determine safety and proper function. However, many of these regulations are antiquated and more appropriately geared to deal with Pressurized Water Reactors on the scale of a base load power stations designed and built using 1970’s-era technology. When it comes to the construction of molten salt reactors or small modular reactors in power modules, these regulations present obstacles that are disproportionate for the level of technical deployment.

Take paperwork, for example. While paperwork is an unavoidable reality of regulatory compliance, American nuclear plants today annually spend between $7 million - $16 million just to document such compliance.[152] As the annual regulatory liability of a nuclear plant today hovers around $60 million, those cost figures add up.[153] And that’s just the costs for running a nuclear power plant. Construction of new plants can only begin after waiting nearly a decade for regulatory approval – a hard sell to any entity that must bleed cash for fees and loan interest before even breaking ground.[154]

This most certainly doesn’t mean that regulations in and of themselves are a bad thing – especially for an industry as sophisticated as atomic energy. But the goal of regulation should be to ensure safety and ideal standards of operation. They shouldn’t hinder the nuclear industry by requiring 2019-era technology to comply with regulations geared to 1970’s-era reactor designs[155] – placing the industry at a distinct financial disadvantage. Nor should they make nuclear technology jump through unnecessary financial hoops, the costs of which are then pointed at to feed a narrative of financial unviability in a self-fulfilling prophecy. We regulate plenty of other sophisticated industries: commercial aerospace, private space ventures, submersible crafts and industrial chemistry without burdening them to insolvency. We can and should do the same with nuclear.

When we summarize the costs behind past implementations of nuclear, we see many of them – non-standardized and ad-hoc construction, outdated regulatory schemas and inappropriately expensive compliance requirements, focus on large size as opposed to modular scalability – are untrimmed fat. Once we start mass-producing small modular reactors for flexible deployment to a single standard, manufacturing costs plummet. As regulations shift towards next-generation nuclear built on that standard, costs of regulatory compliance, research and development, maintenance, and scalability will concordantly follow suit.

Further, in touting renewables as an immediate alternative, advocates correctly celebrate their benefits yet also ignore the costs of renewable integration on a comprehensive or even base load scale. Scarcity Zero’s model seeks to minimize these costs by way of municipal infrastructure. Yet barring a hyperbolically expansive scale of deployment, there’s no way to generate true base load energy on the scale of Scarcity Zero’s target with renewables alone without prohibitively expensive and logistically daunting land purchases. And that’s without looking at the cost of the renewable technology itself, either levelized, maintenance, replacement or end-of-life processing.

It will cost money no matter what energy source we employ to solve future energy needs – and costs will vary depending on how they’re integrated. Both renewables and clean nuclear can and should be employed to their greatest strengths and cost efficiencies. But suggesting that nuclear is too expensive while touting renewables as an inexpensive alternative makes hefty omissions about the ultimate costs of end-to-end renewable implementation. It also makes hefty omissions towards manufacturing, transporting and installing said renewables in a carbon-emitting supply chain – saying nothing of the immense material extraction required to do so. Once those factors are included in the analysis (as we’ll see shortly), the circumstances change quickly.

Criticism: Unproven

In a vacuum, the critics are right: thorium-fueled LFTRs, and for that matter, uranium-fueled Small Modular Reactors, have yet to prove themselves as large-scale viable technologies. But no emergent technology in history has ever arrived to market with “proven viability.” In 1890, the car had unproven viability; the same goes for aircraft in 1910. The computer had unproven viability in the 1970’s. The touch smartphone had unproven viability in the early 2000’s – Microsoft CEO Steve Ballmer famously said the iPhone would “never gain market share.”[156] The internet, even, had unproven viability – one of the foremost computer scientists at the time dismissed it as a fantasy in a February 1995 article in Newsweek entitled “Why The Web Won’t Be Nirvana.” The author, Clifford Stoll, PhD, wrote:

It could be that Mr. Stoll or Mr. Ballmer might find comradery with Mr. Romm, Mr. Thompson, Mr. Rees, and other critics today. Expertise in a specialized focus can lend itself to tunnel vision that hinders views of the larger picture. Emergent technologies always need refinement. That’s how technology works. That’s how it has always worked.

That’s why data storage went from a million dollars per gigabyte in the 1980s to less than ten cents per gigabyte today.[157] That’s why your smartphone, laptop or flat screen television doesn’t cost millions of dollars today. That’s why you can send a video to any continent on the planet within seconds, whereas back when JFK was President an intercontinental call could cost a small fortune.

Technology emerges, designs improve, innovations are incorporated – and the market responds. In an era where we can manufacture error-unacceptable systems on assembly lines in a matter of days, it’s actually quite possible to design and mass produce a technology that avoids the drawbacks of designs chosen in the 1960s specifically because they helped make hydrogen bombs. Now that it’s 2020 and nations worldwide are pouring billions into thorium, there’s no reason to wager they’ll fail, particularly since:

- The 1960’s MSR experiment was successful and proved thorium workable.

- Germany’s THTR-300 proved the thorium fuel cycle workable.

- The Chinese TMSR has proven thorium breeder reactors workable.

- India’s fast breeder reactor has proven the science behind thorium.

- Russia - the only nuclear power on par with the United States - has proven fast breeder reactors workable, and are currently investing in advanced thorium reactors.

- North American companies, including Westinghouse, NuScale Power, Terrestrial Energy, and General Atomics have proven that LFTRs, Small Modular Reactors, and Molten Salt Reactors are all workable.

None of these countries or companies deal in fantasy – and they wouldn’t collectively devote tens of billions to fantasy, either. The thousands of highly educated women and men working with them, their peer-reviewed studies, the prototypes they’ve built and the agencies that issued them grants are all behind the future viability of both thorium and Small Modular Reactor designs.