What About Costs and Criticisms?

It must be mentioned that atomic energy has critics. As is their want, they doubt the technology’s viability on grounds ranging from safety, waste, and proliferation to economic and logistical feasibility. Some see nuclear, in and of itself, as a fundamentally unredeemable technology. Others bring up points that are valid in abstract, yet are used to cast inappropriately generalized aspersions on nuclear’s promise. Thorium, of course, is no exception.

While there are myriad sources that might articulate these criticisms, I’ve chosen three articles for their accessible language and range of arguments. The first two argue against nuclear as a concept, and the third argues against thorium specifically.

I invite you to review them individually, in full, so that you understand where they’re coming from in their own words.

The first article is a February 2019 piece in ThinkProgress entitled “Taxpayers should not fund Bill Gates’ nuclear albatross,” which casts doubt on Bill Gates’ effort to address climate change by increasing nuclear’s American market share.[147][147] The author, Joe Romm, writes:

The second article is from Popular Mechanics, entitled “The Alexandria Ocasio-Cortez 'Green New Deal' Wants to Get Rid of Nuclear Power. That's a Great Idea.”[148] The author, Avery Thompson, had this to say:

Lastly, there’s the thorium-specific criticism written in The Guardian nearly a decade ago.[149] In June 2011, Eifion Rees, an ecologist who advocates for a post-industrial “ecolocracy” (his words), wrote a piece titled “Don't believe the spin on thorium being a greener nuclear option.” In summary, Rees makes the case that thorium is merely a way to deflect attention from the dangers of the uranium fuel cycle within Pressurized Water Reactors that would still be used until thorium had proven large-scale commercial viability.

He states that the nuclear industry itself remains skeptical of thorium and cites the 2010 paper from the UK’s National Nuclear Laboratory[150] mentioned earlier in support. Rees continues that that even if LFTR waste is much shorter lived, it will still be toxic and emit harmful radiation. Rees’s final point is that the effectiveness of renewables is rapidly improving, so even if thorium proves itself in the next 30 years (by Rees’ assessed timeline), it will arrive to solve a problem that’s no longer present. He concludes that the combination of these factors make thorium too new, too untrusted, too potentially dangerous, and too expensive when we already have an energy solution – renewables – in hand.

These articles and mindsets were cited verbatim because I believe in intellectual honesty. They were also cited because they’re wrong. Not just on the facts when it comes to 2020-era technology, but also just as importantly on the role of nuclear in the context of the energy, resource and ecological requirements of our time.

To explain why, we’ll boil down the primary arguments of these three pieces (and the NNL assessment[151] cited in The Guardian) into three overarching criticisms that we’ll review in order.

- Nuclear energy is too expensive in terms of cost and safety, and always will be, thus we should focus exclusively on renewables.

- Thorium’s an unproven technology with unproven viability, thus we should focus exclusively on renewables.

- Thorium advocates overstate its waste and proliferation benefits, thus we should focus exclusively on renewables.

Criticism: Expense

Nuclear power is sophisticated technology, and sophisticated technology costs money. This feeds into a common narrative from nuclear detractors that atomic energy is cost-prohibitive. If waste and proliferation concerns weren’t enough, they say, there’s simply too many expenses behind nuclear engineering, deployment, operation and safety to make the technology viable.

Some of these concerns have merit in abstract. But they don’t necessarily apply to nuclear as a technology any more than concerns about burning zeppelins apply to aircraft as a technology. Further, nearly all focus on Pressurized Water Reactors and point to their drawbacks as cause to paint the entire field of atomic science with a wide brush.

The reason why this chapter focused on smaller LFTRs and made repeated mention of small modular reactors (even if powered by uranium-235) is because they avoid these problems, particularly cost criticisms, by design. Large-scale Pressurized Water Reactors further present major safety hazards if things go wrong, especially as they increase in size. They need massive containment and cooling apparatuses, redundant safety mechanisms, security features, buffer zones and control systems. These highly expensive components are not necessary for LFTR and newer small modular reactor designs. That alone is a differentiating cost factor on the scale of billions of dollars.

Then there’s the fact that most every power plant in America today – nuclear especially – is built as a unique entity, designed and deployed to order. The plant’s concrete, metal, wiring, HVAC, control systems, thermal management, waste processing, plumbing, walkways, stairwells, doors and all points in between are designed, architected and engineered from the ground up each and every time – as is the regulatory approval for each specific building site.

For every nuclear power plant thus far built, a company gathered an architect, structural engineer, nuclear engineer, electrical engineer, environmental engineer, fluid engineer and mechanical engineer to design the plant. Then they hired the contractors to build it, the banks to fund it, the insurance companies to underwrite it, the bond companies to back it, the lawyers to sign off on it and the regulators to approve it. And if they wanted to build another, they then had to wipe the slate clean and do it all over again from scratch because the math and materials that worked for plant A didn’t work for plant B.

It’s no wonder, then, how a nuclear plant can cost billions to construct today. Any system of any level of sophistication would cost the same under those circumstances. If your car had to be built this way, it would cost several million dollars. If a commercial aircraft had to be built this way, it, too, would cost several billion dollars. Automated manufacturing changes this, as it does in any other sophisticated industry. It started with Ford’s assembly line and now works to build jetliners. Once we apply automated manufacturing to nuclear, the same cost effectiveness will be achieved as it has in literally every other industry automated manufacturing has been employed.

Another major additional cost contributor is inappropriate regulation. Nuclear power carries a requisite responsibility of standards and demonstrated operational expertise to develop at scale, and regulations are of course critical to appropriately determine safety and proper function. However, many of these regulations are antiquated and more appropriately geared to deal with Pressurized Water Reactors on the scale of a base load power stations designed and built using 1970’s-era technology. When it comes to the construction of molten salt reactors or small modular reactors in power modules, these regulations present obstacles that are disproportionate for the level of technical deployment.

Take paperwork, for example. While paperwork is an unavoidable reality of regulatory compliance, American nuclear plants today annually spend between $7 million - $16 million just to document such compliance.[152] As the annual regulatory liability of a nuclear plant today hovers around $60 million, those cost figures add up.[153] And that’s just the costs for running a nuclear power plant. Construction of new plants can only begin after waiting nearly a decade for regulatory approval – a hard sell to any entity that must bleed cash for fees and loan interest before even breaking ground.[154]

This most certainly doesn’t mean that regulations in and of themselves are a bad thing – especially for an industry as sophisticated as atomic energy. But the goal of regulation should be to ensure safety and ideal standards of operation. They shouldn’t hinder the nuclear industry by requiring 2019-era technology to comply with regulations geared to 1970’s-era reactor designs[155] – placing the industry at a distinct financial disadvantage. Nor should they make nuclear technology jump through unnecessary financial hoops, the costs of which are then pointed at to feed a narrative of financial unviability in a self-fulfilling prophecy. We regulate plenty of other sophisticated industries: commercial aerospace, private space ventures, submersible crafts and industrial chemistry without burdening them to insolvency. We can and should do the same with nuclear.

When we summarize the costs behind past implementations of nuclear, we see many of them – non-standardized and ad-hoc construction, outdated regulatory schemas and inappropriately expensive compliance requirements, focus on large size as opposed to modular scalability – are untrimmed fat. Once we start mass-producing small modular reactors for flexible deployment to a single standard, manufacturing costs plummet. As regulations shift towards next-generation nuclear built on that standard, costs of regulatory compliance, research and development, maintenance, and scalability will concordantly follow suit.

Further, in touting renewables as an immediate alternative, advocates correctly celebrate their benefits yet also ignore the costs of renewable integration on a comprehensive or even base load scale. Scarcity Zero’s model seeks to minimize these costs by way of municipal infrastructure. Yet barring a hyperbolically expansive scale of deployment, there’s no way to generate true base load energy on the scale of Scarcity Zero’s target with renewables alone without prohibitively expensive and logistically daunting land purchases. And that’s without looking at the cost of the renewable technology itself, either levelized, maintenance, replacement or end-of-life processing.

It will cost money no matter what energy source we employ to solve future energy needs – and costs will vary depending on how they’re integrated. Both renewables and clean nuclear can and should be employed to their greatest strengths and cost efficiencies. But suggesting that nuclear is too expensive while touting renewables as an inexpensive alternative makes hefty omissions about the ultimate costs of end-to-end renewable implementation. It also makes hefty omissions towards manufacturing, transporting and installing said renewables in a carbon-emitting supply chain – saying nothing of the immense material extraction required to do so. Once those factors are included in the analysis (as we’ll see shortly), the circumstances change quickly.

Criticism: Unproven

In a vacuum, the critics are right: thorium-fueled LFTRs, and for that matter, uranium-fueled Small Modular Reactors, have yet to prove themselves as large-scale viable technologies. But no emergent technology in history has ever arrived to market with “proven viability.” In 1890, the car had unproven viability; the same goes for aircraft in 1910. The computer had unproven viability in the 1970’s. The touch smartphone had unproven viability in the early 2000’s – Microsoft CEO Steve Ballmer famously said the iPhone would “never gain market share.”[156] The internet, even, had unproven viability – one of the foremost computer scientists at the time dismissed it as a fantasy in a February 1995 article in Newsweek entitled “Why The Web Won’t Be Nirvana.” The author, Clifford Stoll, PhD, wrote:

It could be that Mr. Stoll or Mr. Ballmer might find comradery with Mr. Romm, Mr. Thompson, Mr. Rees, and other critics today. Expertise in a specialized focus can lend itself to tunnel vision that hinders views of the larger picture. Emergent technologies always need refinement. That’s how technology works. That’s how it has always worked.

That’s why data storage went from a million dollars per gigabyte in the 1980s to less than ten cents per gigabyte today.[157] That’s why your smartphone, laptop or flat screen television doesn’t cost millions of dollars today. That’s why you can send a video to any continent on the planet within seconds, whereas back when JFK was President an intercontinental call could cost a small fortune.

Technology emerges, designs improve, innovations are incorporated – and the market responds. In an era where we can manufacture error-unacceptable systems on assembly lines in a matter of days, it’s actually quite possible to design and mass produce a technology that avoids the drawbacks of designs chosen in the 1960s specifically because they helped make hydrogen bombs. Now that it’s 2020 and nations worldwide are pouring billions into thorium, there’s no reason to wager they’ll fail, particularly since:

- The 1960’s MSR experiment was successful and proved thorium workable.

- Germany’s THTR-300 proved the thorium fuel cycle workable.

- The Chinese TMSR has proven thorium breeder reactors workable.

- India’s fast breeder reactor has proven the science behind thorium.

- Russia - the only nuclear power on par with the United States - has proven fast breeder reactors workable, and are currently investing in advanced thorium reactors.

- North American companies, including Westinghouse, NuScale Power, Terrestrial Energy, and General Atomics have proven that LFTRs, Small Modular Reactors, and Molten Salt Reactors are all workable.

None of these countries or companies deal in fantasy – and they wouldn’t collectively devote tens of billions to fantasy, either. The thousands of highly educated women and men working with them, their peer-reviewed studies, the prototypes they’ve built and the agencies that issued them grants are all behind the future viability of both thorium and Small Modular Reactor designs.

That we need to iron out some present challenges to realizing large-scale commercial deployment isn’t an indictment of the technology – it’s a reflection of opportunity. Every globalized technology in history has risen to meet these challenges, and the international efforts and investments behind thorium stand to repeat the same result.

Criticism: Weapons and Waste

We spoke to weaponization earlier in the chapter. LFTRs and the thorium fuel cycle can be weaponized in theory, but not easily and not practically by military standards. That’s the important distinction: it’s theoretically possible for a state to make a crude bomb with uranium-233 or neptunium-237. But that says nothing about miniaturizing the bomb into a missile-driven warhead or keeping the mechanisms stable for long-term storage, nor the ability to do these things in secret – all of which are required capabilities to present even a moderate threat. Most nuclear powers today have thermonuclear capabilities that uranium-233 or neptunium-237 can’t meet in a best-case scenario, and no state’s going to raise the scales in a conflict to a nuclear fight they’re certain to lose badly.

When considering terrorism, terrorist organizations fundamentally lack the material procurement power and expertise needed to manufacture such a weapon – let alone source the tools needed to do so. And when an inexpensive home gene editing kit[158] or a basic knowledge of industrial chemistry[159] could wreak as much havoc as a dirty bomb, denying humanity the most powerful source of baseload-scale power we have in the abstract name of thwarting terrorism seems foolish.

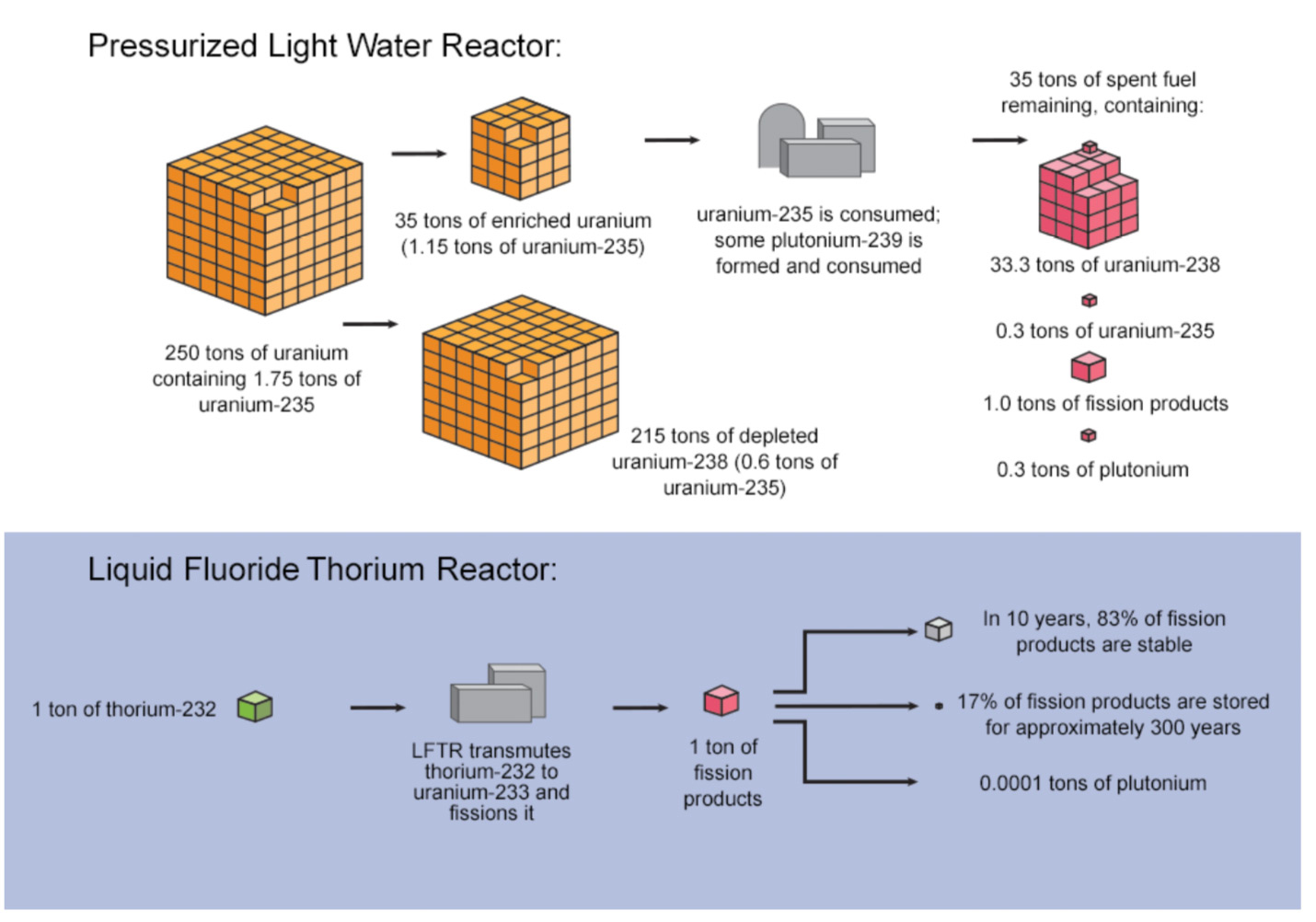

The waste angle, too, is highly contextual. Yes, nuclear waste is dangerous and toxic – including waste from thorium. But thorium’s waste lasts for only 300 years compared to the millennia from waste from the uranium-235 fuel cycle.[160] And most nuclear waste being produced today still has potential to function as fuel within Molten Salt Reactors[161] – which by itself only needs one ton of thorium to generate one gigawatt of energy.[162]

Of the waste that one ton produces, 83% becomes stable in 18 years, with the remaining 17% remaining radioactive for 300 years.[163] It’s well within the realm of feasibility for us to hold that waste in secure underground facilities for that timeline, especially since the most danger occurs only during the first few decades of storage.

Nuclear critics say that’s still unacceptable, and that we’re still better off sticking with renewables. Yet even though renewables are essential for a clean energy future, they’re far from waste free – and it’s highly disingenuous to suggest otherwise. Wind turbines are difficult to recycle and often end up in landfills (the bulldozer in the below-left image is the size of a school bus). Solar panels produce gallium-arsenide (arsenic) and chemical batteries contain strong acids and heavy metals like mercury, lead and cadmium.[165] These are highly toxic substances that don’t lose their toxicity over time as radioactive materials do. Once they leech into the environment, they become a permanent part of it.

Then there’s the question of raw materials. From the table below, we see that the materials required to manufacture solar panels weighs in at 16,447 metric tons per terawatt of generating capacity.[166] At 10,260 metric tons, wind comes in third.[167]

Mindful of Scarcity Zero’s annual generation target of 11.25 trillion kilowatt hours (11,250 terawatt-hours), using these two technologies alone would respectively require 180 million and 113 million metric tons of material. That mass, respectively, is equivalent to 1,800 and 1,125 Gerald Ford-Class aircraft carriers.[168] And that’s just for the United States – applying that approach to the rest of the planet would require billions upon billions more tons of material to just meet global energy demand.

Such figures don’t incorporate the carbon emissions or waste footprint inherent to sourcing these materials in the first place – nor the emissions produced in the manufacture of billions of solar panels or wind turbines. Nor do they incorporate the carbon emissions and cost externalities – both financial and ecological –presented by transporting, installing and wiring billions of solar panels and wind turbines, which, in such implementations, would certainly require vast purchases of expensive land.[169] Think of how many copper or rare earth mines we’d need. How much diesel fuel we’d consume. How many non-recyclable materials or toxic chemicals we’d produce or dispose of at any step of the supply chain.

The waste implications involved with such considerations are enormous, as are the environmental impacts.

For example, the following image shows the Escondida copper mine in Chile:

This image shows the Mountain Pass rare earth mine in California, which sources the lithium-ion needed for advanced batteries.

This image shows the Katanga copper-cobalt mine in Congo-Kinshasa.

Those examples are only three mines of thousands worldwide. Also not shown are the processing plants, smelting facilities, or human toils required in any of the extractive efforts required to rely on a renewable-exclusive portfolio for our future energy needs – nor the ultimate end-state waste created once these systems are ultimately discarded. These considerations, even in a vacuum, carry immense humanitarian and ecological consequences. The following images show child workers mining cobalt and lithium for rechargeable batteries:

These images show large volumes of discarded electronics (e-waste):

Should our civilization move to a renewable-exclusive energy portfolio, these images would barely represent a fraction of the environmental pillaging and humanitarian maladies that would consequently arise. That’s the uncompromising reality of facts as they are.

In this mention, it’s important to re-emphasize that use of lithium-ion, cobalt, copper or rare earth metals isn’t inherently destructive in and of itself – nor are the laudable efforts to switch to either renewables or next-generation battery technology to help wean the global supply chain off of fossil fuels. But it’s nonetheless vital to recognize that exclusive reliance on these technologies in a carbon-emitting manufacturing chain comes with massive ecological and humanitarian consequences that still manifest even if out of sight and mind of the developed-world consumer. The inclusion of such technologies remain central in the Scarcity Zero framework because the negative aspects associated with them would drastically reduce (if not vanish) should the base material and end-state product of both renewables and batteries become sourced, processed and recycled under a clean, carbon-neutral nuclear power schema.

Simply stated: clean nuclear is the key to making renewables truly clean.

Most importantly, the Scarcity Zero framework is made possible only by the cogenerative benefits of high-temperature reactors. Without that energy source, we can’t extract fresh water and hydrogen fuel from billions of gallons of seawater, nor can we initially keep that water hot to store energy generated from renewables on a nationwide scale. We’re left with batteries that carry an intensive material throughput themselves – now on a massive scale – yet without the energy abundance needed to solve resource scarcity. All that effort, time and material invested – along with what would certainly be trillions of dollars – and we’d still be facing the same malady that’s dogged us from the dawn of time.

In that context, storing a few hundred barrels of radioactive material that becomes safe in 300 years is the better option – all the more so since Scarcity Zero still employs renewables to their greatest strengths within municipal infrastructure. But as we’re only able to manufacture renewables in a carbon-free capacity with next-generation nuclear, the numbers behind renewables as a singular solution don’t add up even if we had the capital and material basis to pull off such an endeavor. As we don’t, the waste implications of attempting to do so far eclipse anything nuclear brings to bear – and no amount of selective criticism or ideological advocacy is going to change that.