We build thousands of products on an industrial scale today, but once those products become obsolete, the materials used in them have often not been recycled or repurposed outside of scrap yards. Engineering and financial limitations, difficulties with transporting materials to recycling locations, extant systems with which to recycle them, and the energy necessary to power those systems are all limiting factors. With Scarcity Zero, it's much easier to recycle sophisticated products - either through modular deconstruction, or by using something called plasma gasification to extract useful substances for manufacturing and fabrication elsewhere.

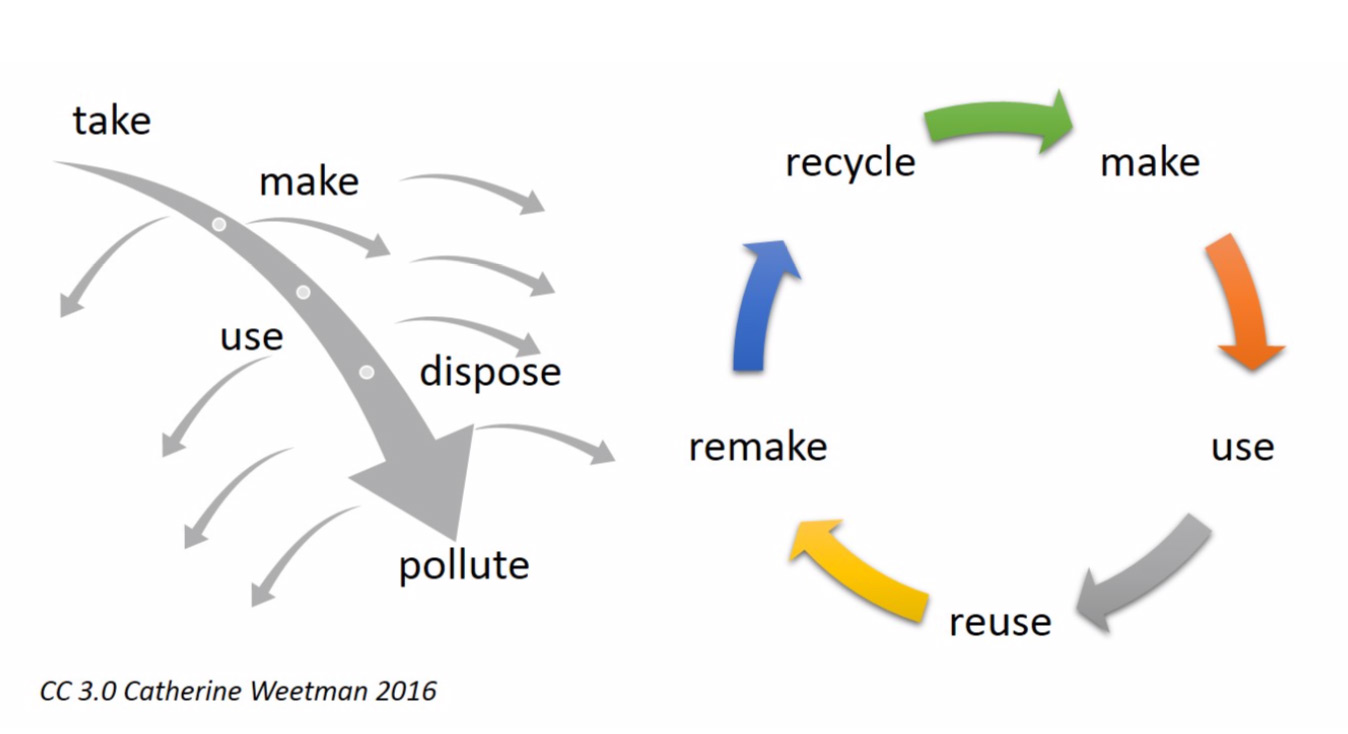

The underlying concept behind this approach is commonly referred to as a “Circular Economy” – an economic system aimed at reducing waste and maximizing efficiency through the continual re-use of resources and materials.[1] In most instances, implementations of circular economies seek to minimize the use of new resources and the creation of waste, pollution and greenhouse gas emissions, and instead employ concepts of refurbishment, re-manufacturing and intelligent recycling at scale to keep already-present resources and materials in play.[2] The underlying idea is that “waste” is contextual, and opposed to a traditional “linear economy” that functions on a production model of “extract, manufacture, sell and dispose” a circular economy leverages as many technological methods as feasible to enable regenerative resources and materials for the “circular” reproduction – and upgrade – of systems in a model that’s as closed-loop as possible.[3]

Linear (left) vs. Circular Economy (right)

Implementations of circular economies are not necessarily novel concepts, and the systems that can accomplish such processes already exist today. But Scarcity Zero significantly increases the scale at which this can be accomplished while lowering energy and resource costs. As a result, we would be able to supplement next-generation manufacturing with recycled metals and materials more effectively than we can today, both reducing the need to acquire new materials and enabling the expansion of circular economic models on nationwide or even global scales. Not only does this improve how we can build things from the design stage, it fundamentally transforms our capabilities to build, recycle and upgrade advanced systems. Examples include:

Intelligent deconstruction: Many products today are simply too complex to be recycled cost-effectively. Consequently, once discarded, they are often thrown in landfills. Reduced energy and material expenses, modern computer systems, and novel engineering methods have lowered the costs of recycling consumer electronics, vehicles, ships, buildings, and airplanes. And as we improve how those things are recycled – or more specifically, disassembled and recycled – this gives us the opportunity to tweak our manufacturing methods to build products that can be disassembled, recycled, and/or upgraded in a modular capacity.

Reduced costs and material requirements: Beyond removing energy as a significant expense, the ability to repurpose older models into newer ones means we don’t have to build new products from scratch. For example: instead of a vehicle going to a scrap yard once it gets old, we could instead engineer that vehicle to be stripped down to its basic components by a factory and refurbished into a newer model – a concept that could be applied to essentially any product.

This form of recycling ultimately benefits both consumers and manufacturers. It gives consumers the ability to exchange obsolete models for credit toward a newer model and reduces the expenses and sweat equity manufacturers pay to acquire materials and create products. These benefits contribute to cost savings for both parties, and also increase the agility of manufacturing by allowing us to do more with what we have currently. Plenty of companies strive to reach this goal, but increasing the number of companies who do so alongside advances in energy generation and material procurement increases the efficacy of this recycling method – promoting its adoption within a greater share of market sectors.

Reduced waste footprint. Waste management, an abundant supply of cheap energy, indefinite supplies of synthetic materials, and deconstruction-focused engineering reduces the waste footprint of manufacturing processes and how we think of discarded products. With Scarcity Zero, we wouldn’t build as many products at the expense of the environment, nor would we build products that are destined for landfills. By upgrading and reconnecting our energy production, material procurement, and manufacturing and recycling processes, the lifecycle of a product is contained from start to finish – reducing nature’s presence in the equation.